High speed cutting gray cast iron is one of the typical applications of PCBN cutting tools. When cutting gray cast iron at high speed, the tool life of PCBN cutting tool can reach 20-30 times that of vitrified tool, which can bring huge economic benefits. For different grades of PCBN cutting tools, the higher the CBN content is, the higher the hardness, wear resistance and thermal conductivity of PCBN cutting tools are. Therefore, the PCBN cutting tool for high speed cutting gray cast iron should be made of grade blank with high CBN content.

According to the application experience of PCBN cutting tool of our company for many years, when cutting gray cast iron with PCBN cutting tool, the following factors have a great influence on the life of PCBN cutting tool.

1.Aging time of casting blank

In the process of solidification, the stress occurs at the grain boundary, which will cause the deformation of the crystal lattice at the grain boundary, resulting in great tensile stress or compressive stress, which will increase the difficulty of chip breaking and increase the resistance of cutting. In the actual production, we find that the aging treated castings have better cutting properties, especially for the castings stored for a long time; when the stress disappears, the chip breaking effect of the grain boundary is obviously improved, and the cutting performance will be obviously improved.

Suggestion: the natural aging time of casting blank should be at least 7 days.

2.Ferrite content of blank in casting

Because the boron element in CBN can react with ferrite, the chemical wear effect of PCBN cutting tool in cutting gray cast iron is enhanced and the service life of tool is reduced.

Suggestion: ferrite content in casting blank is less than 5%, preferably less than 2%.

3.Sulfur content in castings

Because the sulfur element in the gray cast iron material can form a MnS layer on the surface of the PCBN cutting tool during cutting, which plays a certain role in protecting the PCBN cutting tool when cutting.

Suggestion: the content of sulfur in casting blank is not less than 0.05%.

4.Casting surface quality

The blank allowance of the casting is uniform, and no fin or casting head is more beneficial to improve the service life of the insert.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

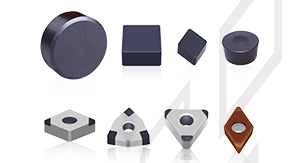

PCBN Insert

Substantially improve cutting efficiency and tool life

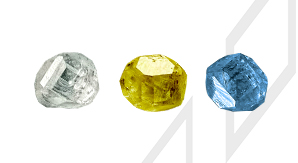

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik