It is recognized that CBN (cubic boron nitride) is second only to diamond in hardness, two times that of diamond in high temperature resistance, four times that of traditional abrasive in wear resistance, and have extraordinary thermal conductivity. There are hundreds of raw materials needed to use CBN to grind in present manufacturing market, from aerospace superalloys and thermal spraying to the hardened steel in automotive bearing and gear industry to improve efficiency and get the shortest processing time. Components and spare parts can get better quality by CBN grinding. Products are optimized to prevent thermal damage during the finishing process. At the same time, the quality consistency of the machined parts is improved. These machining technologies make full use of CBN advantages of increase grinding wheel life and wear reduction. So that the expensive machine can run longer time between the grinding tool replacements and reduce the adjustment time during operation to better meet the requirement of modern automated machine and improve productivity and work efficiency.

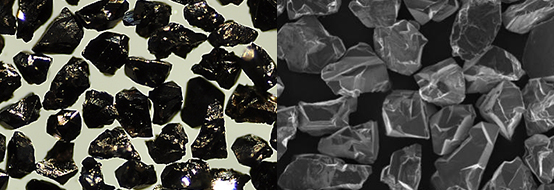

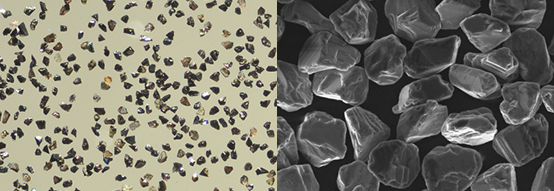

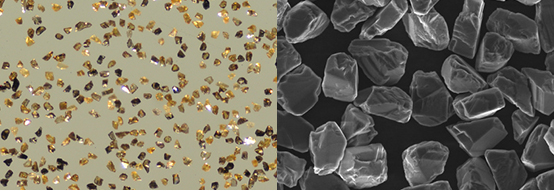

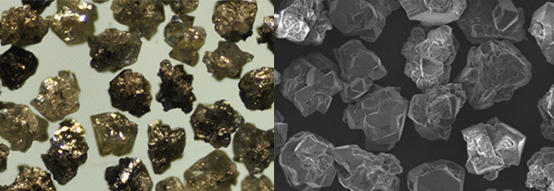

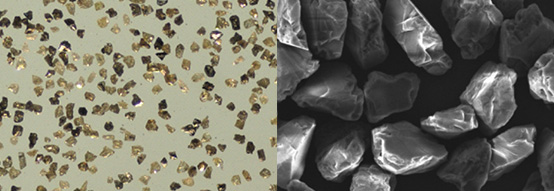

Black, irregular shape, medium strength, high thermal stability, protruding acute angle, providing higher performance and grinding efficiency, and used in resin and vitrified bond system.

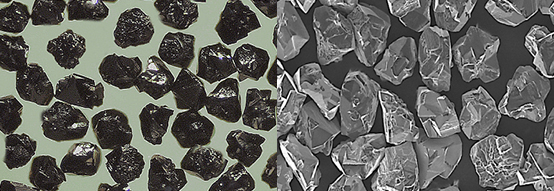

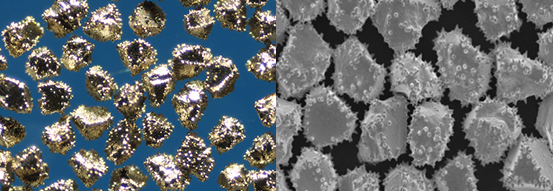

Black, texture structure surface, irregular shape, medium strength, good self-sharpness, good surface finish of machined workpiece, and used in resin and vitrified bond system.

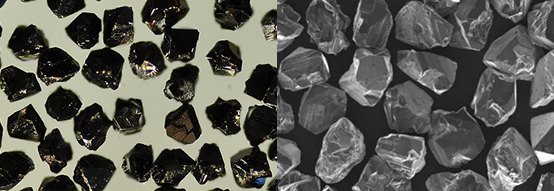

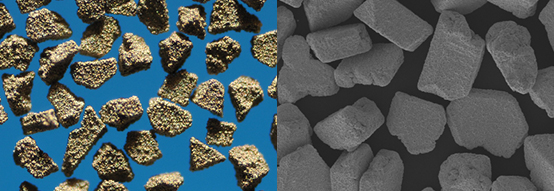

Black, medium blocky, medium strength, high thermal stability, balanced crushing strength and crushing features, combined the grinding efficiency with grinding wheel life, and used in vitrified bond system.

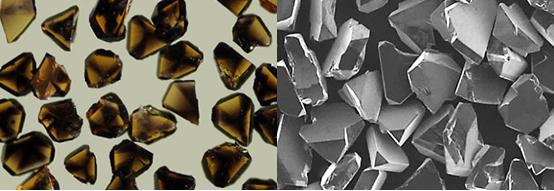

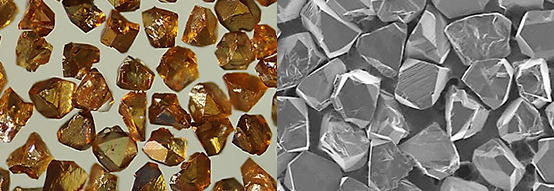

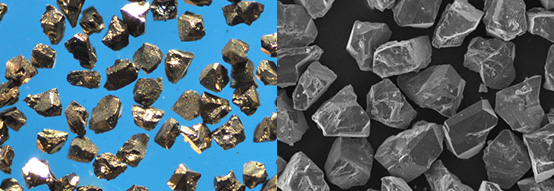

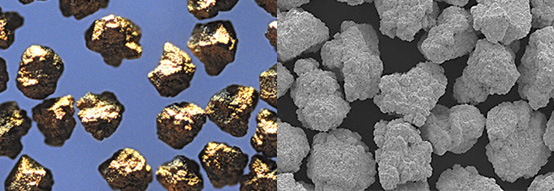

Dark brown, single crystal, irregular shape, sharp acute angle, high strength, high thermal stability. Used in the vitrified, metal and resin bond system with high strength requirement.

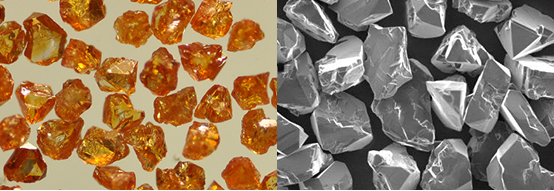

Amber color, medium strength, irregular shape, good self-sharpness, and used in the resin bond system.

Adopting mature electroplating technology, abrasive is plated with different proportion of nickel, which can effectively improve grinding wheel life.

Adopting the mature chemical processing technology, the abrasive is treated with weight increase and nickel coating, which greatly enhances the holding force and heat dissipation ability between the grains and improves the surface finish of the workpiece.

"T" refers to product with titanium-coated surface, and mainly applicable for metal and vitrified bond system. After titanium coating, it can protect the abrasive performance to get higher thermal resistance, and effectively improve the life of the grinding wheel.

Light green, polycrystalline, rough surface, irregular shape, easy fragile, combination of grinding efficiency with service life, and used in the long life and efficient grinding of gemstone, vitrified, glass and carbide tool.

Light green, micropowder, good self-sharpness, and used in high-precision and high-efficiency grinding of ceramic and glass.

Adopting chemical processing technology, abrasive is claded with nickel coating, which greatly enhances the holding force and heat dissipation ability between the grains and improves the service life of the grinding wheel.

|

Grade

Grain size

|

CBN-810 | CBN-815 | CBN-850 | CBN-980 | CBN-950 | CBN-901 | FVG-200 |

| 40/50 | √ | ||||||

| 50/60 | √ | ||||||

| 60/80 | √ | √ | √ | √ | √ | √ | √ |

| 80/100 | √ | √ | √ | √ | √ | √ | √ |

| 100/120 | √ | √ | √ | √ | √ | √ | √ |

| 120/140 | √ | √ | √ | √ | √ | √ | √ |

| 140/170 | √ | √ | √ | √ | √ | √ | √ |

| 170/200 | √ | √ | √ | √ | √ | √ | √ |

| 200/230 | √ | √ | √ | √ | √ | √ | √ |

| 230/270 | √ | √ | √ | √ | √ | √ | √ |

| 270/325 | √ | √ | √ | √ | √ | √ | √ |

| 325/400 | √ | √ | √ | √ | √ | √ | √ |

|

Grade Grain size

|

CBN-M850 | CBN-M990 | FVG-M200 |

| 0-0.25 | √ | √ | √ |

| 0-0.5 | √ | √ | √ |

| 0-1 | √ | √ | √ |

| 0-2 | √ | √ | √ |

| 1-1.5 | √ | √ | √ |

| 1-3 | √ | √ | √ |

| 2-4 | √ | √ | √ |

| 3-6 | √ | √ | √ |

| 4-8 | √ | √ | √ |

| 5-10 | √ | √ | √ |

| 6-12 | √ | √ | √ |

| 8-16 | √ | √ | √ |

| 10-20 | √ | √ | √ |

| 12-22 | √ | √ | √ |

| 15-25 | √ | √ | √ |

| 20-30 | √ | √ | √ |

| 22-36 | √ | √ | √ |

| 30-40 | √ | √ | √ |

| 36-54 | √ | √ | √ |

|

Comparison Table of International Grain Size Standard

|

|||||||||||||

| FUNIK GB/T6406-2016 |

Grain size | 40/50 | 50/60 | 60/80 | 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 |

| Dimension | 425/300 | 300/250 | 250/180 | 180/150 | 150/125 | 125/106 | 106/90 | 90/75 | 75/63 | 63/53 | 53/45 | 45/38 | |

| ISO | Grain size | 427 | 301 | 252 | 181 | 151 | 126 | 107 | 91 | 76 | 64 | 54 | 46 |

| Dimension | 425/300 | 300/250 | 250/180 | 180/150 | 150/125 | 125/106 | 106/90 | 90/75 | 75/63 | 63/53 | 53/45 | 45/38 | |

| FEPA | Grain size | B/427 | B/301 | B/252 | B/181 | B/151 | B/126 | B/107 | B/91 | B/76 | B/64 | B/54 | B/46 |

| Dimension | 425/300 | 300/250 | 250/180 | 180/150 | 150/125 | 125/106 | 106/90 | 90/75 | 75/63 | 63/53 | 53/45 | 45/38 | |

| USA ANSI B74.16-2002 |

Grain size | 40/50 | 50/60 | 60/80 | 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 |

| Dimension | 425/300 | 300/250 | 250/180 | 180/150 | 150/125 | 125/106 | 106/90 | 90/75 | 75/63 | 63/53 | 53/45 | 45/38 | |

| JAPAN JIS4130-1998 |

Grain size | 40/50 | 50/60 | 60/80 | 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 |

| Dimension | 425/300 | 300/250 | 250/180 | 180/150 | 150/125 | 125/106 | 106/90 | 90/75 | 75/63 | 63/53 | 53/45 | 45/38 | |

| RUSSIA 9206-80 |

Grain size | 500/400 | 400/315 | 250/200 | 200/160 | 160/125 | 125/100 | 100/80 | 80/63 | 63/50 | 50/40 | ||

| Dimension | 500/400 | 400/315 | 250/200 | 200/160 | 160/125 | 125/100 | 100/80 | 80/63 | 63/50 | 50/40 | |||

| Theoretical basic size |

Inch | 0.015 | 0.011 | 0.009 | 0.0069 | 0.0058 | 0.0048 | 0.0041 | 0.0034 | 0.0030 | 0.0026 | 0.0022 | 0.0019 |

| Millimeter | 0.378 | 0.288 | 0.226 | 0.174 | 0.148 | 0.123 | 0.103 | 0.086 | 0.075 | 0.066 | 0.057 | 0.048 | |

Please fill in the following information and describe the product demand information as much as possible. We will process your inquiry asap.