Super grinding tools (consolidation grinding tools) are generally composed of abrasive, bond and pore, which have an important influence on the properties of grinding tools, so abrasive, bond and pore are usually called the three elements of grinding tool. Among the three elements of super grinding tool, super abrasive is the main raw material of the grinding tool, constitutes the skeleton of the grinding tool and is the main substance that plays the role of grinding in the grinding tool. Many edges and corners exposed on the surface of the grinding tool are the cutting edges of the machined workpieces. As a super abrasive used in grinding, it should have the following properties: (1) high hardness and wear resistance; (2) proper crushing resistance and self-sharpening; (3) with high temperature stability, it can maintain its inherent hardness and strength at grinding temperature; (4) chemical stability is not easy to react with machined materials. The main physical and chemical properties of superabrasives determine the abrasive properties mentioned above, which are not only the basic indexes to judge the quality of abrasive, but also the important factors affecting the manufacturing process and quality of grinding tool.

(1)Hardness of abrasives and its effect on the properties of grinding tool

Hardness is a main index that determines the grinding performance of abrasives. The hardness of super abrasive is mainly affected by the bonding force between particles in the crystal structure of abrasive, and then by crystal form, temperature, manufacturing technology and so on. Diamond and cubic boron nitride abrasive are typical covalent bond minerals. In the grinding work, it is necessary to ensure that the hardness of the abrasive is higher than that of the grinding workpiece, but the hardness of the abrasive is not constant, a large amount of grinding heat will be produced in the grinding process, and the abrasive hardness will change under the action of heat. Therefore, at the use temperature, the abrasive must maintain a certain hot hardness in order to give full play to the performance of the grinding tool.

(2)Toughness of abrasives and its effect on the properties of grinding tool

In the process of grinding, abrasives are affected by both grinding force (tangential force and radial force) and impact force at the same time. The ability of abrasives to resist breaking under the combined action of grinding force and impact force is called the toughness of abrasives. The toughness of super abrasive is an important index affecting the self-sharpening of grinding tool. If the toughness of the abrasive is too high, in the grinding process, when the abrasives are blunt, the abrasives will not break itself to reveal the new edge under the action of grinding force, thus affecting the grinding efficiency of the grinding tool. However, if the toughness is poor, under the action of grinding force, the abrasives will be broken too fast and not carry out effective grinding. Therefore,the appropriate toughness of abrasives is the need to achieve effective grinding.

(3)Compressive strength of abrasives and its effect on the properties of grinding tool

The compressive strength of super abrasive refers to the ability of abrasives to resist external pressure, which is related to the degree of crystallization, chemical bond, grain shape and crystal form of the abrasive. The compressive strength of the abrasive directly affects the performance of the abrasive itself and the cutting ability of the grinding tool in the process of use. For example, the compressive strength of CBN is very high, which means that it can keep the grains intact and not easy to break when used under harsh conditions.

(4)The coefficient of thermal expansion of abrasives and its effect on the properties of grinding tool

Superabrasives have the same phenomenon of thermal expansion and cold shrinkage as other substances. The coefficient of thermal expansion of abrasive refers to the elongation of abrasives at unit temperature. The thermal expansion coefficient of abrasive is mainly related to its crystal structure, chemical bond strength, chemical composition, purity and temperature. The thermal expansion coefficient of the abrasive should be basically the same as that of the vitrified bond in the vitrified grinding tool; otherwise, cracks are easy to occur in the bond connection chain because of the inconsistency of expansion and shrinkage in the firing process, especially in the cooling process of the grinding tool, so as to reduce the strength of the grinding tool, and even cause the grinding tool to crack seriously.

(5)Packing density and theoretical density of abrasives and their effects on the properties of grinding tool

①The packing density of abrasives: there are two kinds of packing density of abrasives; one is the natural packing density, which refers to the mass per unit volume of the abrasive in the natural state, and its main influencing factor is the external vibration; another one is the compact packing density, which refers to the real-time packing density of abrasives fully subjected to external force vibration, and the packing density of grains is related to the shape of the grains, the filling method of the packing and the matching of the grains. The shape of the abrasive does not belong to the sphere but to equal area shape, sheet shape, strip shape and so on.

The packing density of abrasives is an important performance index in the process of grinding tool manufacturing, which affects the formability, hardness and strength of grinding tool, and ultimately affects the grinding performance of grinding tool. Under the same formula, if the packing density is unstable, the hardness and strength of the grinding tool will be also unstable. The abrasive packing density is high, so is the strength and hardness of the grinding tool. In vitrified bond superhardgrinding tool, the fluctuation of abrasive packing density is often one of the important factors affecting the hardness of grinding tool.

②Theoretical density of abrasives: the theoretical density of abrasives is also referred to as density, which refers to the mass per unit volume of abrasives without voids. The theoretical density of the abrasive is mainly determined by the composition and crystal structure of the abrasive itself.

(6)Chemical composition of abrasives and its effect on the properties of grinding tool

Chemical composition is the main index that determines the performance of abrasives, which directly affects the strength, toughness, grinding performance and appearance color of abrasives. The chemical composition of abrasives not only directly affects the performance of abrasives, but also affects the performance of grinding tool. The higher the purity of the abrasive is, the better the hardness and grinding performance are, and the hardness and grinding performance of the corresponding grinding tool are better. For vitrified bond superhard grinding tool, the influence of the chemical composition of abrasives on the properties of grinding tool is particularly prominent.

(7)The shape of abrasive and its influence on the performance of grinding tool

The abrasive shape is various, and the common shapes are equal area shape, sheet shape and strip shape. It is generally desired that the abrasive shape is equal product shape, because it has higher compression, bending and impact resistance than flake and strip abrasives, and can improve the cutting ability of grinding tools. If it is used to process workpieces with high toughness, it is appropriate to use more grains with equal area shape. The abrasive shape is mainly related to the crushing method in the machining process, which directly affects the compressive strength, flexural strength, impact strength and cutting ability of abrasives, as well as the packing density of abrasives. Abrasives of different shapes can also improve their performance through shaping and selection process, so as to improve the performance of grinding tools.

As the core raw material in the manufacturing of grinding tools, the influence of superabrasives on the manufacturing process and performance of grinding tool is self-evident. The performance of the superabrasive can be reflected by the product quality index, and the product performance can be controlled by controlling the production technology and quality testing standards of the product. Therefore, in order to produce grinding tools with good performance, we must have a more comprehensive understanding of the properties and functions of superabrasives.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

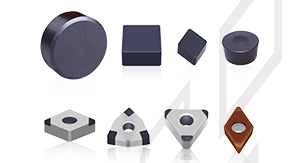

PCBN Insert

Substantially improve cutting efficiency and tool life

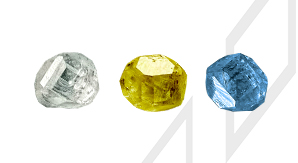

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik