Camshaft is the key part of automobile engine, and the machining efficiency and quality affect the cost and service life of components to a great extent. Camshaft is a kind of non-circular grinding workpiece with large machining margin and difficult grinding, which requires high grinding precision and efficiency and is difficult to machine. The processing technology of cam is the focus of attention in the industry.

In the traditional technology, the technical difficulties in camshaft grinding are as follows: (1) The precision of cam profile is low, and it is difficult to improve. (2) Camshaft belongs to slender shaft parts, which has poor rigidity and easy to deform and bend. This process change will also affect the grinding surface quality. (3) The surface of the cam is easy to produce defects such as burns and cracks, so it is difficult to improve the production efficiency. (4) It is difficult to grind the camshaft. In the process of grinding, the force on the camshaft surface is different, the grinding vibration occurs, and the ripple appears on the part surface, which affects the overall quality of the camshaft machining.

The quality of CBN abrasive will determine the grinding quality of camshaft, camshaft needs high strength grinding, CBN abrasive grinding has strong sharpness, good thermal stability and durability, and its hardness and strength can meet the requirements of camshaft grinding strength. Diamond has the highest hardness and leaves traces on the surface of machined workpieces, so it is not suitable for precision grinding such as high-speed steel and camshafts.

Vitrified bond CBN grinding tool has the advantages of high grinding efficiency, good shape retention, high durability, easy dressing, high abrasive utilization rate and long service life of grinding wheel, so it has become the first choice for high efficiency and high precision grinding. At present, vitrified bond is used in CBN grinding wheels for camshaft machining.

Most automobile factories in industrialized countries have used CBN grinding wheels to grind camshafts, using CBN special CNC camshaft grinders and high-speed and high-performance vitrified CBN grinding wheels. The grinding machine needs good stability and good rigidity conditions. At this time, the vibration ripple of camshaft grinding with CBN grinding wheel can be reduced. On the full CNC grinding machine, the length of the ripple can be controlled below 0.7mm, and the depth of the ripple can be controlled below 0.5 μ m. The working speed of the vitrified bond CBN grinding wheel can reach 120-160m/s, the correction interval of the grinding wheel is 100 times that of the ordinary grinding wheel, and the service life of the grinding wheel is more than 50 times that of the ordinary grinding wheel, which greatly improves the machining efficiency, machining precision and machining life, and can significantly reduce the comprehensive production cost.

A large amount of grinding heat will be produced in the grinding process of CBN, and when the heat dissipation effect of the camshaft is poor, the workpiece will overburn or deform, so the cooling device will be added in the process of CBN’s machining the camshaft. The use of coolant will minimize the grinding damage and improve the quality requirements of the machined surface.

The application of CBN grinding technology in the processing and application of camshaft can meet the grinding requirements of complex camshaft through precision grinding. If the grinding accuracy and roughness are controlled within the range of 0.05mm, the overall grinding level of camshaft is obviously higher.

Therefore, when machining camshaft, selecting high hard CBN abrasive to solve the problem of difficult grinding of camshaft can greatly improve the machining efficiency, machining precision and machining life, and can significantly reduce the comprehensive production cost. At the same time, the grinder with good rigidity and shock resistance is selected to effectively reduce the ripple caused by grinding, and coolant is used to reduce the thermal deformation and damage caused by the thermal diffusion of the camshaft, so as to achieve high-speed and high-precision grinding of the camshaft.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

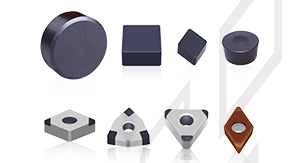

PCBN Insert

Substantially improve cutting efficiency and tool life

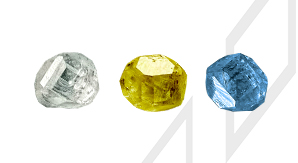

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik