With the rapid development of high-speed grinding and ultra-precision grinding technology, higher requirements for grinding wheels are put forward. Metal bond grinding wheels have been widely used in production because of their remarkable characteristics, such as high bonding strength, good formability, long service life and so on. Metal bond CBN grinding tools are divided into sintered metal bond and electroplated and brazed metal bond grinding tools according to the types of raw materials and production processes, which are mainly used in polishing and grinding cutting edge of high-speed steel cutting tools and PCD cutting tools, grinding excircle of automotive camshaft and crankshaft and other fields. The sintered metal bond CBN grinding tool has the advantages of high strength, good toughness, good thermal conductivity, long service life and so on. According to the different metal elements and alloy composition in the bond, it can be divided into copper-based, cobalt-based, titanium-based and iron-based categories. Electroplated and brazed grinding tools use electroplating and brazing processes to consolidate single-layer CBN abrasives on the metal matrix through metal binders such as silver, nickel or titanium, so that the grinding tool’s exposed degree of abrasives is more than 40%, which greatly increases the chip space and makes the abrasives sharper during grinding.

Compared with other types of grinding wheels, metal bond CBN grinding wheel has the following advantages:

(1)The utilization rate of abrasives per unit volume is high. Compared with ordinary grinding wheel, metal bond CBN grinding wheel contains fewer abrasives per unit wheel volume. Under the condition of the same total cutting force, metal bond CBN grinding wheel will have greater cutting pressure on each working abrasive, and most of the abrasives work in the normal "cutting" state, and the abnormal "friction" and "ploughing pear" states are less, so the chips formed are thicker.

(2)Compared with vitrified bond and resin bond grinding wheels, it can bear higher grinding pressure. This is because the total pressure of the abrasives of diamond bond CBN grinding wheel on the workpiece makes the CBN abrasive keep in close contact with the workpiece, and the support between CBN abrasive and its bond is very strong.

(3)The cutting sharpness can be maintained for a long time.

The CBN abrasives used in metal bond CBN grinding tool are different from the CBN abrasives used in vitrified bond and resin bond grinding tools in terms of variety and performance. There are the following requirements for the selection of CBN abrasives:

(1)The strength of CBN abrasives generally requires varieties with medium strength series.

(2)For the choice of grain size, according to the different requirements of processing procedure and roughness, and according to the order of rough grinding, semi-finishing grinding and fine grinding, the grain size can be selected in the range of 50/60~230/270. The processing roughness corresponding to these granularity can reach Ra1.6~0.2 generally.

(3)The grain shape of CBN abrasive used for the preparation of metal bond CBN grinding tool, should have the characteristics of good crystal shape. Generally it is block, and equal volume crystal, with smooth crystal surface and regular edges and corners. The grains with these characteristics have medium strength and medium brittleness. The shape of grains is not only an important factor to determine the strength, but also one of the important factors affecting the packing density.

(4)The surface quality is strictly required. The surface state of CBN abrasives is related to the bonding strength between CBN abrasive and metal bond, which affects the hardness and strength of grinding tools, and ultimately affects the service life of grinding tools.

Tool life and machining efficiency are the main performance indexes of metal bond CBN grinding wheel. How to give full play to the role of super abrasive and enhance the holding ability of metal bond to CBN abrasive are still the key factors affecting the life of metal bond CBN grinding wheel.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

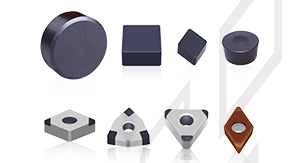

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

PCBN Insert

Substantially improve cutting efficiency and tool life

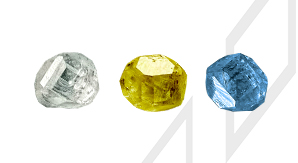

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik