Polycrystalline Diamond, short for PCD, is a kind of composite material composed of diamond and cemented carbide, which is usually prepared by assembling diamond powder with a certain amount of bond and cemented carbide matrix and then sintered under the condition of ultra-high temperature and high pressure.

PCD has the characteristics of high wear resistance and hardness, low friction coefficient and high thermal conductivity, which makes PCD cutting tool can achieve high speed, high efficiency and high precision machining. It has a wide application prospect in aerospace, automotive, electronics, wood, stone and other fields.

1.1. Performance characteristics of PCD

(1)High hardness and wear resistance

PCD has the characteristics of high hardness, high compressive strength, good thermal conductivity and wear resistance, and can achieve high machining precision and efficiency in high speed cutting. This characteristic of PCD cutting tool is determined by the crystal state of diamond, and the structure has strong bonding force and directionality, so that diamond has very high hardness.

(2)Isotropic, uncleaved plane

PCD is a kind of polymer synthesized by a certain method from small diamond grains of micron or submicron size. The disorder of disordered accumulation of grains leads to its isotropy, which can exert the best performance in cutting workpieces without the need to choose the direction, and it is not easy to split along a single cleavage plane, so the mechanical properties are optimized.

(3)High machining precision

PCD cutting tool has low thermal expansion coefficient and high elastic modulus, so it is not easy to deform in the cutting process; at the same time, it can reduce the cutting force and cutting temperature, improve the cutting tool durability and cutting rate, and obtain a good machined surface.

(4)Low friction coefficient

PCD has low friction coefficient and low affinity with non-ferrous and non-metallic materials, so it can not only reduce the deformation and cutting force, but also does not produce chip tumor in cutting, which greatly reduces the surface roughness of the machined workpiece.

(5)High thermal conductivity

The thermal conductivity of PCD is very high, which is better than silver and copper, and much higher than ordinary cemented carbide, so it is easy to dissipate heat in the cutting process and the cutting temperature is lower.

2. Application of PCD

(1)Application of PCD in automobile and aeronautics and astronautics

PCD cutting tools are mainly used for machining skirt, pin hole, cylinder block and gearbox of engine piston in automobile field. Due to the high silicon content of these parts (more than 10%), the service life of the cutting tool is high, and the durability of the PCD cutting tool is 1-50 times that of the cemented carbide cutting tool, which can ensure the dimensional stability of the parts, and greatly improve the cutting speed, machining efficiency and surface quality of the workpiece.

In the aerospace field, the cutting rate of aluminum alloy (AlSi2) cylinder head machined by PCD cutting tool is higher, and the tool life is about 20 times higher than that of cemented carbide, and the surface quality of the workpiece is also greatly improved.

(2)Application of PCD in wood processing industry

Wood processing is also an important field in the application of PCD cutting tools. With the rapid development of synthetic boards (such as medium density fibreboard, particleboard, composite floor board and so on), the demand for super-hard tools is accelerated, and PCD cutting tools gradually replace the traditional woodworking tools in the market.

The Al2O3 in the outermost layer of the laminated floor has a great wear on the cemented carbide cutting tool, and the use of PCD cutting tool can effectively solve this problem. Therefore, the main market of PCD in the woodworking industry is the processing of laminated flooring and high hardness fibreboard.

(3)Application of PCD in electronic processing industry

In the electronic industry, the requirements for the production of electrical printing board are getting higher and higher, general cutting tools will have rough edges in use, which will affect the installation and positioning of electrical components, and the whole printing board is not beautiful; cemented carbide cutting tools are in machining, short life, slow processing speed, low efficiency and poor machining accuracy. Using PCD cutting tool, the machining efficiency is high, the processing cost is low, and the application is wide.

(4)Application of PCD in glass cutting industry The cutter wheel made of PCD is mainly used for high precision and high quality cutting of LCD screen of electronic products, as well as cutting glass for construction and automobile at the same time. Both mandrel and cutter wheel are made of PCD material, which has the advantages of high machining precision, wear resistance, good consistency and long service life, so it is an ideal substitute for ordinary glass cutter and cemented carbide glass cutter wheel.

(5)Application of PCD in composite material industry

When the glass fiber reinforced composites are machined with PCD cutting tool, the tool life is about 60 times that of cemented carbide cutting tools, the processing cost of one piece is 1/20 of that of cemented carbide tools, and the machining precision is higher than that of cemented carbide cutting tools.

Because of its good processing quality and processing economy, PCD shows unique advantages in the fields of non-metallic materials, non-ferrous metals and alloys, composite materials and so on. If the double substitution of high-speed steel and cemented carbide cutting tools is realized, the market space of PCD cutting tools will be more huge.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

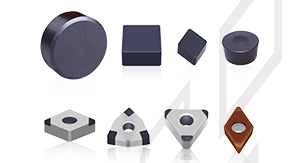

PCBN Insert

Substantially improve cutting efficiency and tool life

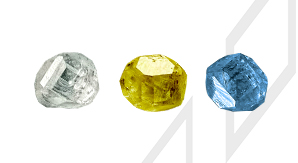

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik