The correct selection and application of cutting tool edge treatment is considered to be one of the basic elements for the successful manufacture and correct use of hard turning tools. For different application conditions, the insert treatment has different treatment forms and parameters. Cutting tool edge treatment of cutting tool refers to a process on cutting edge after fine grinding of insert and before coating (if any), through chamfering, honing, leveling, polishing and other treatments so as to improve the quality and service life of cutting tool.

1.The forms and characteristics of cutting edge treatment

Generally speaking, the cutting edge treatment can be divided into four categories: F-no chamfer or blunt circle, E-blunt circle without chamfer, T-chamfer without blunt circle, S-chamfer and blunt circle. The four kinds of cutting edge treatment have their own physical and geometric characteristics, which have different effects on the stress state, tool-chip friction and chip shape.

1.1F-shaped cutting edge treatment. F-shaped cutting edge treatment, that is, neither chamfer nor blunt circle. This cutting edge treatment method is sharp, small cutting force, small shear deformation and low cutting heat, but the cutting edge strength is low, and the cutting edge has initial defects, so it is rarely used.

1.2E-shaped cutting edge treatment. E-shaped cutting edge treatment, that is, no chamfer but blunt circle. The insert adopts blunt circle technology, which eliminates the machining micro-defects on the cutting edge, strengthens the edge, and increases the resistance to tool chipping and cracks.

1.3T-shaped cutting edge treatment. T-shaped cutting edge treatment, that is, chamfer but no blunt circle. Through chamfering treatment, it has good impact resistance, and it can replace S-shaped cutting edge when cutting force is required to be reduced and tolerance is required to be high.

1.4S-shaped cutting edge treatment. S-shaped cutting edge treatment, that is, chamfer + blunt circle. This form is the most common cutting edge treatment, and it is also the preferred insert type in hard turning. It has higher strength than T-type, which is more resistant to edge chipping and cracking, is easier to predict cutting tool life, and can produce more stable workpiece surface quality. It is especially suitable for large cutting depth and intermittent processing.

2.The influence of S-shaped cutting edge treatment on cutting

In the treatment of S-shaped cutting edge, the chamfering angle has two sides. On the one hand, increasing the angle can improve the strength of the tool and increase the impact resistance of the cutting tool; on the other hand, the tool becomes blunt and increases the cutting heat, which is disadvantageous to the wear resistance of the rake face. This is because the increase of the angle is equivalent to a larger negative rake angle, so the shear angle becomes smaller, the deformation increases, and the deformation heat is high, so the wear of the rake face is accelerated. At the same time, the chamfering width should also adapt to the setting of processing parameters. If the chamfering width is too small, the chamfering effect will be weakened, and the friction between the chip and the rake face will wear quickly at the junction of the chamfer and the original rake face. If the width of the edge is too large, it will increase the cutting force and prolong the friction distance between the chip and the rake face, which is not conducive to the tool life. At the same time, the size, uniformity and machining model of the blunt circle will also have a certain impact on the performance of the tool.

PCBN cutting tools generally use negative rake angle and chamfer treatment in hard turning, which can not only strengthen the edge, but also improve the wear resistance of the tool, and provide different cutting edge strength in machining hardened steel or gray cast iron. After grinding with diamond grinding wheel, there are often different degrees of micro-chip (i.e. micro cutting edge chipping and saw) on the cutting edge. In the cutting process, the micro-chip of the cutting tool edge is very easy to expand, which speeds up the tool wear and damage. Through negative rake angle design and chamfer precision grinding, the strength of the tool is improved, and the blunt circle treatment is adopted to eliminate the machining micro-defects on the cutting edge. The two treatment methods improve the impact strength of the cutting tool and increase the wear resistance of the cutting tool, so as to prolong the tool life.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

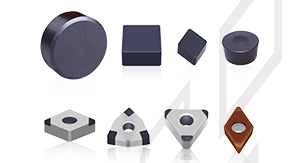

PCBN Insert

Substantially improve cutting efficiency and tool life

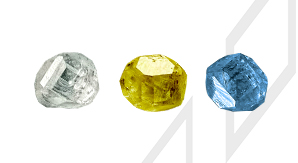

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik