The PCD cutting tool must have a good cutting edge before machining the workpiece, and diamond grinding wheel is the most widely used method at present. The results show that the higher the quality of the cutting edge is, the finer the tool mark at the junction of the geometric reflection area of the tool on the machined surface is, and the higher the surface finish of the machined workpiece is. Because it is very easy to cause tool wear or damage that the cutting edge is chipped or extended, and then the service life of the tool is reduced. The cutting edge chipping is the key index of the quality of cutting edge for diamond cutting tool.

The grinding mechanism of PCD cutting tool: the abrasives of diamond grinding wheels constantly impact PCD materials, resulting in brittle crushing (including intragranular micro-crushing, intergranular crushing and cleavage crushing), sliding wear and scratching of diamond on PCD, while thermochemical action is the oxidation or graphitization of diamond caused by high temperature in the grinding process. There are many factors affecting the cutting edge quality of PCD cutting tools, such as the grain size of diamond powder in PCD compact, the type of diamond grinding wheel, the performance of equipment, the rigidity of fixture and so on.

1.The grain size of diamond powder in PCD compact

Under the same other conditions, there is a positive correlation between the grain size of diamond powder and cutting tool edge chipping of PCD material, that is, the larger the grain size of diamond powder is, the greater the cutting edge chipping is. At the same time, the cutting edge chipping of the mixed grain size is smaller than that of the coarse grain and closer to the medium grain size, this is because the pure coarse grain is filled with metal bond, and the mixed grain size has both bond and other fine grain size between the coarse grains.

In the process of grinding, the abrasives of the grinding wheel diamond continue to impact the edge of the PCD cutting tool, the plasticity of the PCD cutting tool is poor, and the cutting edge will have micro edge chipping. From the microscopic point of view, the diamond grains in the PCD cutting tool appear brittle crushing and chipping during extrusion and friction, and the size of the chip formed by brittle crushing is positively related to the grain size of the diamond powder, and the larger the grain size is, the larger the cutting edge chipping is. In addition, the diamond abrasive hardness of the fine grinding wheel is lower than that of the diamond grains in the medium and coarse grain PCD, the scratching effect of the abrasive is weak, but the abrasive of the fine grinding wheel is easy to wear and clog, when the grinding temperature is high, the friction and thermochemical action are dominant, and the larger chip in brittle crushing is reduced or eliminated, so the final cutting edge chipping is smaller than the grain size.

2.Types of diamond grinding wheels

The order of cutting edge chipping: metal bond grinding wheel > vitrified bond grinding wheel > resin bond grinding wheel. When the grain size of grinding wheel is more than W10, the value of cutting edge chipping is very sensitive to the grain size of grinding wheel and increases with the increase of grain size, while when the grain size of grinding wheel is less than W10, the value of cutting edge chipping is not sensitive to the grain size of grinding wheel.

The abrasives of metal bond diamond grinding wheels are broken in order to maintain the sharp state in the process of grinding, so as to realize grinding. The surface of resin bond diamond grinding wheels will be deformed due to heat, so it is appropriate to adopt lower grinding speed. Vitrified bond is made of many kinds of materials, and the bond and diamond abrasives are easy to fall off collectively in the grinding process, resulting in pits on the surface of PCD cutting tools.

3.Equipment speed

In the process of grinding PCD cutting tools, higher or lower rotational speed can not guarantee the quality of the cutting edge, and a moderate rotational speed is needed to obtain the minimum cutting edge chipping. The rigid accuracy of the grinding machine affects the range of the optimal rotational speed.

4.Grinding pressure

In general, the maximum value of cutting edge chipping increases with the increase of grinding pressure. With the increase of grinding pressure, the extrusion effect of single abrasive on PCD will be enhanced, which makes PCD more prone to cleavage fracture and fatigue fracture. If the pressure is too small, the grinding efficiency is low, and if the pressure is too high, the cutting edge is easy to chip, so it is necessary to determine the appropriate grinding pressure according to the condition of the equipment.

To sum up, the most important thing for the edge quality of PCD cutting tool grinding with diamond grinding wheel is not to produce cutting edge chipping. It is necessary to determine the appropriate processing technology according to different grades of PCD to ensure a good cutting edge, and then prolong the service life of PCD cutting tool and improve the surface quality of machined workpiece.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

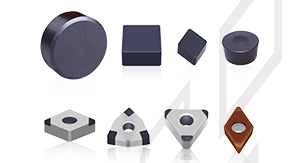

PCBN Insert

Substantially improve cutting efficiency and tool life

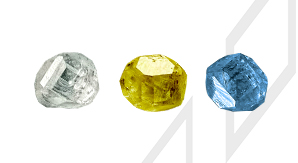

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik