PCD cutting tools can process all kinds of wood from natural wood to particleboard, medium and high density fibreboard, etc. In recent years, the rapid development of artificial panels has promoted the further application of PCD woodworking tools. In particular, the development of artificial panels such as medium density board, plywood, particleboard and composite floor accelerates the demand for super-hard tools in the wood processing industry, so that PCD cutting tools gradually replace the position of traditional woodworking tools in the market. Reinforced composite floor is welcomed by users because of its wear resistance, waterproof and moisture proof, corrosion resistance, convenient installation and so on. The outermost layer of Al2O3 has a great influence on the wear of cemented carbide tools, but the particularity of its structure determines the special requirements of tools in the machining process. PCD cutting tools can effectively solve this problem.

High hardness, high wear resistance, high thermal conductivity, low friction coefficient and good shape retention of cutter teeth are the main characteristics of PCD cutting tools. In the wood processing industry, the cutting speed of PCD woodworking cutting tools can reach 3000 m/min-5000 m per minute, and the cutting capacity can reach tens of meters per minute; the use of PCD cutting tools can greatly reduce the downtime and change time, and its service life is tens or even hundreds of times longer than that of cemented carbide cutting tools.

PCD woodworking cutting tools can be divided into two categories: PCD milling cutter and PCD saw insert. The main varieties of PCD milling cutter are: special PCD floor milling cutter for machining wood flooring, PCD furniture milling cutter and so on. The special PCD floor milling cutter mainly refers to the PCD milling cutter for machining reinforced wood flooring. This kind of milling cutter has complex shapes and many kinds, including PCD horizontal pre-milling cutter, PCD longitudinal pre-milling cutter, PCD trimming cutter, PCD finishing cutter, PCD tenon forming cutter, PCD groove forming cutter, PCD chamfering cutter, PCD lock forming cutter and so on. In machining, these cutting tools should be combined according to different needs in order to produce floors of different varieties, thickness and tenon types. The PCD saw insert can carry out long-time, deep and ultra-high speed cutting without stopping and grinding, and the cutting section is of better quality. At present, PCD woodworking circular saw inserts are used more and more, and are gradually replacing the traditional cemented carbide circular saw inserts. Table 1 shows the comparison of the durability of PCD and cemented carbide cutting tools.

Table 1 Comparison table of tool durability between PCD and cemented carbide cutting tools

|

|

Cutting saw insert |

Trimming plate milling cutter |

End milling cutter |

Routing and milling cutter |

|

Carbide cutting tool |

1-30,000 m |

2 pieces |

15 pieces |

200 pieces |

|

PCD cutting tool |

10-400000 m |

650 pieces |

3000 pieces |

10000 pieces |

|

Durability ratio |

About 10 times |

About 325 times |

About 200 times |

About 50 times |

|

Material |

Laminated particleboard |

High density flax board |

High density fibreboard |

Hardwood laminate |

Compared with the ordinary woodworking milling cutter, the PCD woodworking milling cutter has larger diameter, more teeth and higher rotational speed, which can effectively improve the milling accuracy. The PCD milling cutter has the advantages of sharp edge, high machining and installation precision and good dynamic balance performance, which can effectively improve the production efficiency on the premise of ensuring the machining quality. The most prominent feature of the cutting tool angle parameter is the significant increase of the wedge angle, because the diamond cutting tool has high hardness and poor impact resistance, the cutting edge is easy to break under the action of external force, and the increase of the wedge angle avoids the cutting edge chipping to a certain extent and improves the service life of the cutting tool.

In processing, different processing materials should choose different grades of PCD compact, instead of simply pursuing high hardness and wear resistance. Coarse-grained PCD cutting tools are relatively more wear-resistant but easy to break. Finer-grained PCD can grind a higher quality cutting edge, resulting in better surface machining quality and better insert toughness. In processing the Al2O3 surface strengthening layer of the aggrandizement floor, the coarse-grained material should be selected, and the finer-grained composite sheet can be selected in processing the middle layer of the floor to improve the finish of tenon and grooves.

PCD woodworking cutting tool is effective tool for wood machining and the specific geometric parameters of the PCD cutting tool depend on the condition of the workpiece and the comprehensive machining conditions of the tool material and structure. Because the PCD cutting tool is often used in the finishing machining of workpiece, the cutting thickness is small, so it belongs to micro-cutting, so its relief angle and flank have obvious influence on the machining quality. Smaller relief angle and higher flank quality can play an important role in improving the machining quality of PCD cutting tool.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

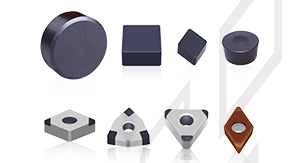

PCBN Insert

Substantially improve cutting efficiency and tool life

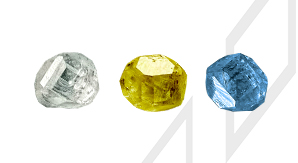

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik