The wire cutting machine uses Mo wire or Cu wire as the tool electrode, passes through the workpiece at a certain rate, applies pulse voltage between the processed materials, and maintains a certain gap. The gap is full of insulating medium, so that spark discharge occurs between the electrode and the processed material, and is consumed and corroded each other, and countless pits are etched on the surface of the workpiece, making it a product that meets the requirements of size and shape precision. The cut of PCD compact machined by WEDM (WEDM) is smooth and the appearance quality is excellent.

The factors that affect the surface quality of PCD WEDM workpiece are as follows:

1.Open circuit voltage

If the open circuit voltage is low to a certain extent, it will hinder the smooth formation of the discharge channel, thus affecting the processing rate of WEDM. Especially for the inhomogeneous polycrystalline diamond material, which contains non-conductive diamond phase, it will hinder the smooth formation of the discharge channel. In a certain range, there is a positive relationship between the processing rate and the open-circuit voltage.

2.Peak current

The increase of peak current will increase the pulse energy, thus increase the material etching amount of the pulse and increase the cutting rate. The smaller the peak current is, the greater the proportion of thermal energy loss in the pulse energy is. When the peak current is less than a certain value, the thermal energy loss increases with the increase of the peak current; with the increase of the peak current, the thermal energy loss is maintained at a relatively stable value, and when the current is too large, it will lead to the deterioration of the working conditions in the discharge area and reduce the cutting rate.

3.Discharge pulse width

The width of the discharge pulse is related to the energy of a single pulse, and the prolongation of the discharge duration means the increase of the discharge energy of the single pulse. With the increase of the pulse width, the cutting rate increases and tends to be stable, but it does not increase infinitely, which may be due to the deterioration of the working conditions around the discharge channel and the lack of energy concentration, resulting in the decrease of energy efficiency.

4.Electrode wire

With the extension of processing time, the wear degree of the electrode wire increases, the elasticity becomes smaller, the brittleness increases, and the wire is easily broken. On the surface of the machined workpiece, obvious stripes can usually be seen, this is because the force of the electrode wire in the uplink, downlink process and the moment of commutation is uneven, the electrode wire can not be too loose, the overloose beat will be more serious. But it can not be too tight, the tension of the wire is too large, it is easy to break the wire, and the force on the guide wheel and bearing is increased, which leads to the damage of the guide wheel and bearing.

5.Diamond grain size

The diamond grain size of PCD compact also has an effect on the efficiency and quality of WEDM. With the increase of diamond grain diameter, the difficulty of WEDM of PCD compact increases, the time is prolonged, and the machining quality decreases.

6.The thickness of diamond layer and the overall thickness of PCD compact

In general, the thicker the diamond material layer of the same brand is, the more difficult the WEDM machining is, the slower the speed is, and the longer the machining time is; the thicker the overall thickness of PCD compact is, the greater the difficulty of WEDM machining is, the slower the speed is, and the longer the machining time is.

7.The influence of the entry direction of electrode wire

In the WEDM machining of PCD compact, the electrode wire can enter the workpiece from the PCD layer or from the cemented carbide layer. The cutting time from the PCD layer to the cemented carbide layer in the wire walking direction is lower than that in the opposite direction, because the wire walking drives the flow of liquid, and the working condition of the entry end of the electrode wire is much better than that of the electrode wire away from the beginning.

8.The phenomenon of over-corrosion in WEDM

The phenomenon of over-corrosion is easy to occur in the WEDM machining process of PCD compact, and the over-corrosion may make the cutting tool size accuracy can not be guaranteed. This is due to the existence of cobalt-rich layer between polycrystalline diamond layer and cemented carbide layer, and the Co element has excellent electrical conductivity and is easy to be removed. The cobalt-rich layer is produced in the sintering process of PCD compact. Due to the concentration difference at high temperature and high pressure, the cobalt in the cemented carbide layer tends to permeate to the polycrystalline diamond layer.

One of the main factors affecting the amount of overerosion is the open-circuit voltage. The open-circuit voltage is added to the two electrodes to provide the electric potential energy generated by the discharge channel. When the electric field intensity reaches a threshold, the discharge channel will be formed. The electric field strength is proportional to the open-circuit voltage, and the higher open-circuit voltage allows a larger discharge gap, which means that the electrode wire can discharge and remove corrosion on the cemented carbide material in a larger range.

To sum up, during, by using WEDM, processing PCD compact and related products, it is necessary to take into account the processing quality, cost and efficiency, and select appropriate processing parameters according to different brands and specifications to ensure the effect of WEDM.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

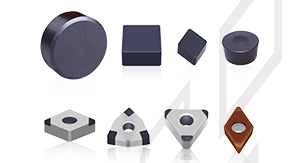

PCBN Insert

Substantially improve cutting efficiency and tool life

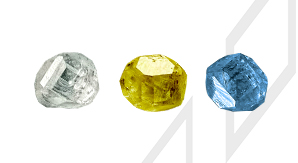

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik