The brazing technology is indispensable in the application of PCD compact. Vacuum brazing has the advantages of accurate brazing temperature, uniform heating, many brazing points at the same time, no surface treatment after brazing and so on. The size of the cutting tool product for vacuum brazing should not be too large and must be able to be put into the vacuum furnace. At the same time, the tool material must be able to withstand the temperature change during the brazing process and maintain its own performance. Vacuum brazing process is especially suitable for mass-produced PCD cutting tools with small size and can be heated as a whole, and it can braze multiple points at a time, but it is not suitable for PCD product with larger size or that can only accept local heating.

For PCD cutting tool products, vacuum brazing process can be divided into preparation work before entering the furnace and vacuum brazing process in the furnace. Preparation: For PCD tool products to be vacuum brazed, select appropriate vacuum solder (usually solder paste) and apply it correctly to the insert groove, then place the insert in a fixed position to be cured by solder paste; furnace: Put the processed PCD cutting tool products into a vacuum furnace, seal and vacuum continuously, and then heat, melt solder, complete brazing action, cool and get out of the furnace according to the procedure in vacuum. The purpose of vacuum brazing is to make the molten solder evenly distributed to all parts of the brazing seam under the action of capillary pipette, so as to achieve the ideal brazing effect.

(I)The factors affecting the preparation of vacuum brazing are shown in Table 1.

Table 1

|

Influencing factors |

Indicators |

Result |

|

You need to choose the right solder |

A good fusion reaction occurs |

It is recommended to choose low melting point Ag-based solder |

|

Roughness of brazing interface |

Ra: 0.7-1.6 |

Too smooth surface affects the diffusion reaction between matrix, solder and insert; too rough surface leads to poor fluidity of solder |

|

braze size |

0.05-0.2mm |

The intensity of too much ambassador weakens; if it is too small, the effect of capillarity is not enough |

|

Surface state of cutter grain |

Remove oxide, stains, etc. |

It is easy to cause virtual brazing |

|

Vacuum degree |

10-3 |

If it is too small, it will affect the strength and appearance |

|

Maximum heating rate |

Do not cause segregation |

Heating rate directly affects efficiency |

(II)Technological conditions

When the temperature is below the solidus, the solder itself is relatively stable, and there will be no softening, modification and other problems; when the temperature is higher than the liquidus, the solder will completely melt and maintain the properties of the alloy; but when the temperature is between the solidus and the liquidus, if the time is not long, the solder is only in the softening or partial melting state, and there will be no qualitative change; if it is in this temperature range for a long time, segregation will occur. Once the segregation occurs, the performance of the solder will change, which will affect the brazing effect. Therefore, in the brazing process, it is necessary to quickly raise the temperature from the solidus to above the liquidus, so as to prevent the possibility of segregation of solder, so as to better ensure the stability of brazing quality. The process conditions are shown in Table 2.

Table 2

|

Process name |

Action |

Description |

|

Initial warming |

Heating up |

Adjust the speed according to the equipment conditions, only affect the efficiency |

|

Heat preservation below solidus |

Keep the cutting tool at a safe temperature to achieve consistency |

The holding time is determined by the equipment and the amount of furnace installed, which is generally 10-40min |

|

Breakthrough liquidus |

Quickly cross the dangerous temperature area |

The faster the heating rate, the better. Being too slow can easily lead to segregation |

|

Heat preservation above liquidus |

Capillary action - brazing |

The holding time is determined by the equipment, the amount of furnace charge and the size of the braze |

|

Cooling with the furnace |

Complete brazing |

Take it out when the temperature decreases, otherwise it is easy to be oxidized by air |

In a specific temperature range, the wettability of the solder is proportional to the brazing temperature; at the same brazing temperature, the brazing strength increases at first and then decreases with the extension of holding time; the flow blocker is suitable for products with high appearance requirements, it can effectively prevent the solder from adhering to the non-brazed surface.

To sum up, for PCD cutting tools, vacuum brazing process can effectively eliminate the influence of air on PCD and keep a good appearance of cutters. The heating temperature in the vacuum furnace is uniform, the deformation of the product is small, and the tool is not easy to crack. Under the condition of stable process, the product quality of each furnace is consistent, which is especially suitable for mass production of small size PCD cutting tools.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

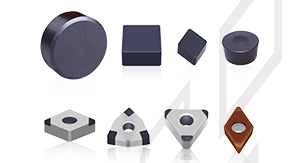

PCBN Insert

Substantially improve cutting efficiency and tool life

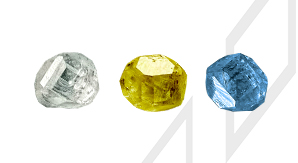

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik