PCD cutting tool material has the advantages of high hardness, good thermal conductivity and low friction coefficient, which reduces cutting force, slows tool wear and makes the cutting process more stable, which is conducive to reducing surface roughness. The workpiece surface can achieve mirror effect in high-speed turning, so it is an ideal tool material for turning aluminum alloy at present. In the process of use, attention should be paid to the surface roughness of the workpiece and the wear of the cutting edge.

The factors affecting the surface roughness of aluminum alloy workpieces are shown in theTable 1:

Table 1

|

Influencing factors |

Change |

Roughness change |

|

Feed rate |

Increase |

Increase |

|

Cutting speed |

Increase |

Stabilize after decreasing to a certain value |

|

Cutting depth |

Increase |

Not obvious |

|

Diamond grain size |

Increase |

Increase |

The wear form of PCD cutting tool for machining aluminum alloy cutting edge is different from that of traditional cutting tool, which is mainly manifested as adhesive wear, diffusion wear and damage of polycrystalline layer, and its characteristics are shown in Table 2.

Table 2

|

Cutting edge wear form |

Characteristics |

|

Adhesive wear |

By using different cutting speed, process aluminum alloy, the phenomenon of sticking knife and chip tumor are not seen with the naked eye, and the wear mode is not the main one. |

|

Diffusion wear |

It has excellent diffusion wear resistance when cutting aluminum alloy, which is very suitable for machining aluminum alloy. |

|

Damage of polycrystalline layer |

The physical and mechanical damage is caused by the impact of the cutting edge in the machining process, resulting in a slight chip or the loss of binder, resulting in the spalling of diamond grains to form a gap. The breakage of the polycrystalline layer will directly affect the machining accuracy and make the workpiece scrapped. At present, it is the main cause of PCD wear. |

The main countermeasures for cutting edge wear are as follows:

(1)Reasonable selection of PCD grade

PCD cutting tools with high strength, good toughness, good impact resistance and fine grain size should be selected for finishing or ultra-finishing, and coarse-grained PCD should be selected for rough machining. The thicker the PCD grains are, the stronger the wear resistance of the tool is. On the premise of ensuring the machining accuracy and quality, the coarse-grained PCD is preferred.

(2)Reasonable selection of cutting edge types

Table 3

|

Cutting edge types |

Characteristics |

Suitable for processing aluminum alloy |

|

Sharp angle |

The cutting edge is sharp and the cutting is light, which can obviously reduce the cutting force, improve the quality of the machined surface and reduce the formation of burrs. |

Finishing of low silicon aluminum alloy |

|

Blunt circle |

If the cutting edge of the cutting tool is honed into an R angle, the risk of insert breaking can be reduced obviously. |

Medium/high silicon aluminum alloy |

|

Chamfer |

Increase the edge of the insert to make it more stable, but the pressure and cutting resistance of the insert will also increase during cutting. |

Heavy-duty cutting of High Silicon Aluminum Alloy |

(3)Reasonable selection of cutting tool angle

The principal deflection angle of PCD cutting tool mainly plays a role in improving cutting tool strength and distributing cutting force in aluminum alloy machining, such as small main deflection angle, long cutting width, small force per unit cutting edge length, increase of principal deflection angle, decrease of radial force, stable cutting, increased cutting thickness and good chip breaking performance.

(4)Reasonable selection of cutting tool radius

The cutting tool radius is a radius formed at the intersection of the main cutting edge and the secondary cutting edge. For machining, the radius enhances the strength of the cutting tip. Under the same feed, the larger the radius is, the better the surface roughness is. When the same machining roughness is obtained, the insert with large radius can achieve low speed and large feed. In general, the larger the radius, the better, but limited by the cutting depth and the rigidity of the workpiece and machine tools, a matching value is needed, not the larger the better.

(5)Reasonable selection of processing parameters

In general, the cutting speed of aluminum alloy machined by PCD cutting tool is recommended to be within 4000m/min, and the hole machining speed is recommended to be within 800m/min. If the feed rate is too large, it will increase the residual geometric area of the workpiece and lead to the increase of cutting force; if the feed rate is too small, it will increase the cutting temperature and reduce the cutting life, and the feed rate is generally recommended to be 0.08-0.15mm/t. Increasing the cutting depth of the PCD cutting tool will increase the cutting force and the cutting heat, which will increase the tool wear and easily lead to cutting edge chipping. However, too small cutting depth will cause work hardening, accelerate tool wear and even cutting edge chipping.

To sum up, when machining aluminum alloy workpieces, the PCD grade should be reasonably selected, the tool shape should be designed reasonably, and the correct machining process parameters should be reasonably selected so that the surface finish of the machined workpiece is good, the cutting tool wear degree is reduced, the tool service life is prolonged and the production cost is reduced.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

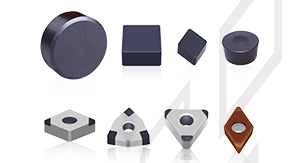

PCBN Insert

Substantially improve cutting efficiency and tool life

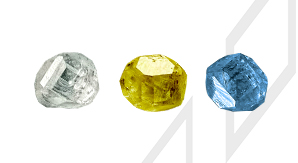

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik