Cubic boron nitride, CBN, is an ideal material for processing iron group materials because of its high hardness, good thermal stability and chemical stability, and chemical inertia to iron group elements at high temperature, which is second only to diamond. Cubic boron nitride gringding tools are a series of tools with certain shape and performance, which are made of CBN as abrasive and with the help of bonds and other auxiliary materials under certain conditions, such as grinding wheels, grinding heads, cutting pieces, grinding plates, oilstones and so on. Among them, CBN grinding wheel grinding tools are the most common. According to the classification of bonds, CBN grinding wheel can be divided into three types: metal bond CBN grinding wheel, resin bond CBN grinding wheel and vitrified bond CBN grinding wheel. Compared with other bonds, the vitrified bond has some disadvantages, such as high brittleness and long production cycle, but because of its good heat resistance, good shape retention, many pores and adjustable, easy repairing and other advantages, its proportion in CBN grinding wheel system is increasing year by year, and it has become the largest family of CBN grinding tools.

Compared with other bond CBN grinding wheels, vitrified bond CBN grinding wheels have the following characteristics:

(1)With controllable porosity. The pores on the surface of vitrified bond CBN grinding wheel have the functions of chip holding, chip removal, enhanced heat dissipation and cooling. According to the purpose of grinding, the size and number of pores in vitrified bond CBN grinding wheel can be adjusted and controlled by means of studying vitrified bond and adjusting grinding wheel formula.

(2)Good cutting performance. Due to the open structure of vitrified bond CBN grinding wheel, CBN abrasives can be best exposed. The resulting grinding wheel has excellent free cutting performance, high workpiece material removal rate, low grinding force, low specific grinding energy and good grinding performance.

(3)It has good thermal stability and chemical stability. In the vitrified bond CBN grinding wheel, on the one hand, the vitrified bond has good heat resistance, which can make full use of the high thermal stability of the CBN abrasive and achieve longer service life of the grinding tool; on the other hand, the excellent chemical stability of the vitrified bond makes the grinding tool adapt to a wide range of grinding fluid.

(4)Good rigidity. Vitrified bond CBN grinding wheel is more suitable for high precision and low roughness grinding because of its small thermal expansion coefficient, good rigidity and small knife during grinding.

(5)Good self-sharpness. The vitrified bond CBN grinding wheel has the advantages of good self-sharpening, easy dressing, long dressing interval and low dressing frequency; the correction and dressing can be completed at one time, and the maintenance cost is low.

(6)The integrity of the machined workpiece is good. The surface integrity of the workpiece ground by vitrified bond CBN grinding wheel is good, the quality of the workpiece is high, and the service life of the grinding wheel is longer.

Vitrified bond CBN grinding wheel belongs to multi-component vitrified matrix composites composed of CBN abrasive, auxiliary abrasive, bond and other materials in terms of macroscopic composition. In the preparation process of grinding wheel, we should pay attention to the following points:

(1)The vitrified bond should match the thermal expansion coefficient between the CBN abrasive and the auxiliary abrasive in order to ensure the firm bonding between them.

(2)There is no obvious chemical reaction between vitrified bond and CBN abrasive, so as to avoid the damage of surface structure of CBN abrasive and the deterioration of hardness and other main properties.

(3)Under the condition of the preparation of grinding wheel, the properties of CBN abrasives and main materials can not be degraded.

(4)According to the performance of grinding workpiece material (such as material, hardness, etc.), machining model, machining allowance, machining precision requirements and other factors, the type, grain size, concentration and wheel hardness of CBN abrasives should be reasonably selected to meet the specific grinding requirements.

Vitrified bond CBN grinding wheel has been used in many manufacturing fields, such as automobile, aviation, machine tool, bearing, engineering ceramics and so on because of its superior performance. Because of its high thermal conductivity, vitrified bond has the potential to be used in high-speed and high-efficiency grinding. With the continuous emergence and application of high-end grinding equipment, vitrified bond CBN grinding wheel will be used more and more in all kinds of grinding, such as molding, high efficiency, high precision grinding and so on.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

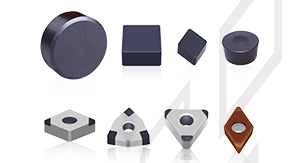

PCBN Insert

Substantially improve cutting efficiency and tool life

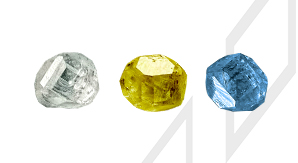

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik