I. Characteristics of ultra high speed grinding technology

In recent years, in order to comprehensively meet the requirements of modern industrial technology and high-performance scientific and technological products for machining accuracy, surface quality and machining efficiency of mechanical parts, some advanced grinding technologies have emerged. Among them, the development of ultra-high speed grinding technology characterized by ultra-high grinding wheel cutting speed and super abrasive grinding wheel is the most eye-catching. The VS of the ordinary grinding wheel is generally less than 50m/s, high speed grinding when VS is greater than 50m/s, and ultra high speed grinding when VS is greater than150 m/s.

Ultra-high speed grinding technology is known as "the highest peak of modern grinding technology". CIRP has identified ultra-high-speed grinding technology as one of the central research directions facing the 21st century. Compared with general grinding, high-speed grinding and ultra-high-speed grinding have the following outstanding advantages: (1) greatly improve the grinding efficiency, reduce the number of grinding machines and reduce the cost; (2) small grinding force, low grinding temperature, good precision and integrity of the machined surface; (3) improving the durability of the grinding wheel is helpful to realize the automation of grinding, and (4) it can realize the grinding of difficult-to-machining materials (nickel-based heat-resistant alloy, superalloy, aluminum and aluminum alloy, etc.).

II. Application advantages of CBN in ultra high speed grinding

Cubic boron nitride and diamond grinding wheels are called super abrasive grinding wheels, which are the guarantee of high efficiency and high speed grinding. Compared with diamond abrasives, cubic boron nitride (CBN) abrasives have higher thermal stability, heat resistance, thermal conductivity and chemical inertia to iron group elements at high temperature, while vitrified bonds have good chemical stability, oil resistance, heat resistance, acid and alkali resistance, and suitable for many kinds of grinding fluids. The produced vitrified bond CBN grinding wheel is porous, which can increase the gullet-to-chip space and improve the heat dissipation performance of the grinding wheel, so the vitrified bond CBN grinding wheel still keeps stable and high hardness at higher service temperature. It not only has the advantages of good cutting edge, low grinding force, high production efficiency, long service life, easy shaping and sharpening, etc., but also because of the low specific grinding energy of CBN, the vitrified bond grinding wheel has the advantages of high cutting edge, low grinding force, high production efficiency, long service life, easy shaping and sharpening, etc. In the removal of large metal, the protection of the workpiece can be realized, the burn of the workpiece can be avoided, the feed speed can be increased on the basis of ensuring the grinding quality, and the production efficiency can be greatly improved. Therefore, vitrified bond CBN grinding wheel has become the first choice for ultra-high speed grinding with high efficiency, energy saving and high precision at the same time.

III. Requirements for CBN of ultra-high speed vitrified grinding wheel

1. Requirements for CBN quality

CBN abrasives used in vitrified bond will be eroded to a certain extent by bond’s various components with fluxing action, such as alkaline oxide (Na2O, K2O, Li20), in the sintering process of grinding tool, resulting in the erosion and refinement of well-crystallized and angular CBN single crystals, the loss of effective cutting ability and the damage of CBN strength. Therefore, it’s required that the selected CBN single crystal must have the characteristics of complete crystal shape, no defects, good heat resistance and high strength.

2.Requirements for grain size of CBN

The grain size of CBN abrasive reflects the geometric size of abrasives and is one of the main characteristic indexes of grinding wheel. The selection of abrasive grain size should mainly consider the requirements of surface roughness and machining efficiency of the machined workpiece. Fine abrasives or polycrystalline and microcrystalline abrasives should be selected in ultra-high speed finishing. However, the grain size is too fine, the grinding force on each abrasive is too small, so that the abrasive is not easy to cut into the workpiece, which will affect the grinding efficiency. Therefore, a coarser grain size is generally selected on the premise of meeting the processing requirements. Sometimes mixed abrasives (CBN with complementary toughness and brittleness, brittleness and different grain sizes) are used to improve the durability of the grinding wheel. Table 1 shows the corresponding table of grain size and grinding mode at ordinary speed. It can be used as a reference for ultra-high speed grinding, but the corresponding relationship of the table needs to be modified because of the particularity of ultra-high speed grinding.

Table 1 Selection of grain size size in grinding method

|

Grinding mode |

Rough grinding |

Semi-fine grinding |

Fine grinding |

Super fine grinding |

|

Granularity |

50/60-120/140 |

120/140-200/230 |

200/230-W36/54 |

W22/36-W0/0.5 |

Note: it comes from Modern Grinding Technology, by Li Bomin and Zhao Bo.

3.Requirements for CBN concentration

Concentration is one of the important characteristics of CBN grinding wheel, which has a great influence on ultra-high speed grinding efficiency and machining cost. The concentration of CBN grinding wheel should not be too low, otherwise the grinding efficiency is not high. High concentration can bring high grinding ratio, but if the concentration is too high, many abrasives will fall off prematurely and cause waste. The concentration of CBN grinding wheel is mainly selected according to the type of bond and the grain size of abrasive. At present, high concentration is used in ultra-high speed and high efficiency grinding, and the concentration of vitrified bond CBN grinding wheel is generally more than 125%. For example, some imported vitrified CBN grinding wheels generally have a concentration of 175% ~ 200%.

As a key tool in ultra-high speed grinding technology, ultra-high speed grinding vitrified bond CBN grinding wheel plays a very important role in the research and application of ultra-high speed grinding technology. At the same time, the manufacturing technology of ultra-high speed vitrified CBN grinding wheel is also a highly integrated process system, including grinding wheel matrix design and manufacturing technology, CBN abrasive selection and treatment technology, vitrified bond preparation technology, grinding tool formula and size design, grinding tool forming and firing technology, grinding wheel follow-up processing and testing technology and so on. Therefore, the reasonable selection of the characteristics of ultra-high-speed vitrified CBN grinding wheel has a direct and essential impact on the ultra-high-speed grinding efficiency, grinding speed, grinding quality and so on.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

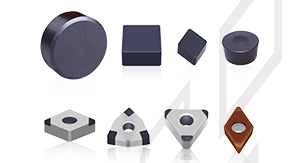

PCBN Insert

Substantially improve cutting efficiency and tool life

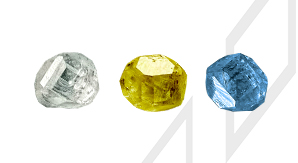

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik