Grinding is a processing method of removing excess materials from the workpiece with super abrasives, which can process materials of any hardness. As a traditional machining model, it can obtain high workpiece precision and surface quality, high processing efficiency and low cost. It occupies a very high proportion in the field of advanced manufacturing. Different grinding methods will produce different grinding defects in the application process, and the most influential factor on grinding defects is grinding wheel. This paper describes in detail the defects caused by the specific grinding wheel factors and the corresponding dressing methods, as shown in the table below.

Table 1 Common problems and solutions of grinding wheel in the process of grinding

|

Serial number |

Name of grinding method |

Grinding defect name |

Grinding defects caused by grinding wheel factors |

Dressing method |

|

1 |

External circular grinding |

Straight ripples occur on the surface of the workpiece |

Poor balance |

Correctly balance grinding wheel |

|

2 |

External circular grinding |

Straight ripples occur on the surface of the workpiece |

Too high or uneven hardness |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

3 |

External circular grinding |

Straight ripples occur on the surface of the workpiece |

Have been used blunt, not sharp, uneven wear |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time. |

|

4 |

External circular grinding |

Straight ripples occur on the surface of the workpiece |

The newly trimmed grinding wheel is not sharp |

If the dressing is too fine or the diamond has been worn, choose the correct dressing method and dosage according to the grinding requirements |

|

5 |

External circular grinding |

There is a spiral shape on the surface of the workpiece |

The hardness of the grinding wheel is too high and the dressing of the grinding wheel is too fine |

The grinding wheel should be selected correctly according to the characteristics of the workpiece and the grinding requirements and the selection rules of the grinding tool. Select correct dressing method and dosage according to grinding requirements |

|

6 |

External circular grinding |

There is a spiral shape on the surface of the workpiece |

The thermal deformation of machine tool is unstable when dressing grinding wheel |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

7 |

External circular grinding |

There is a spiral shape on the surface of the workpiece |

The dressing is not timely, the wear is not uniform, and the grinding fluid is insufficient when dressing the grinding wheel |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

8 |

External circular grinding |

The surface of the workpiece is brushed and scratched |

Shedding of abrasive |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

9 |

External circular grinding |

The surface of the workpiece is brushed and scratched |

Improper selection of abrasive and grain size of grinding wheel |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

10 |

External circular grinding |

The surface of the workpiece is brushed and scratched |

Empty abrasive left or embedded on the surface after dressing the grinding wheel |

When grinding softer metals and non-ferrous metals with coarse-grained grinding wheels, the specimens should be ground first so that the protruding abrasives fall off before grinding |

|

11 |

External circular grinding |

Workpiece surface burn |

The hardness is too hard or the grain size is too fine |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

12 |

External circular grinding |

Workpiece surface burn |

Improper selection of abrasives and bond |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

13 |

External circular grinding |

Workpiece surface burn |

The dressing is too fine and the grinding wheel is blunt and not trimmed in time |

According to the grinding requirements, the correct dressing method and dosage should be selected, and the characteristics of the workpiece and the changing law of precision should be grasped and the grinding wheel should be trimmed in time |

|

14 |

External circular grinding |

The workpiece is tapered |

Poor finishing, uneven wear or sharpness |

According to the grinding requirements, the correct dressing method and dosage should be selected, and the characteristics of the workpiece and the changing law of precision should be grasped and the grinding wheel should be trimmed in time |

|

15 |

External circular grinding |

The workpiece is in the shape of a drum or a saddle

|

Poor forming accuracy |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

16 |

External circular grinding |

The workpiece is in the shape of a drum or a saddle

|

The grinding wheel is not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

17 |

External circular grinding |

The surface of the workpiece is brushed and scratched |

The corner is worn or the busbar is not straight |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

18 |

External circular grinding |

The verticality of the end face of the workpiece is over-poor |

The contact between the end face of the grinding wheel and the workpiece is too large |

Trim the grinding wheel to reduce the contact surface and select the appropriate grinding wheel |

|

19 |

External circular grinding |

The verticality of the end face of the workpiece is over-poor |

The wear of grinding wheel is not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

20 |

External circular grinding |

Workpiece roundness error |

The grinding wheel is not sharp or worn unevenly |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

21 |

Internal circular grinding |

Straight ripples occur on the surface of the workpiece |

The connecting shaft is long and thin, and the rigidity is poor |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

22 |

Internal circular grinding |

Straight ripples occur on the surface of the workpiece |

The grinding wheel is not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

23 |

Internal circular grinding |

Straight ripples occur on the surface of the workpiece |

Vibration caused by too large diameter of grinding wheel |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

24 |

Internal circular grinding |

Straight ripples occur on the surface of the workpiece |

The vibration is caused by the excessive connection length between the grinding wheel and the workpiece |

grinding wheel to reduce the contact surface and select the appropriate grinding wheel |

|

25 |

Internal circular grinding |

There is a spiral shape on the surface of the workpiece |

Bad contact between grinding wheel and workpiece |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

26 |

Internal circular grinding |

The surface of the workpiece is brushed and scratched |

The contact area between grinding wheel and workpiece is too large |

Trim the grinding wheel to reduce the contact surface and select the appropriate grinding wheel |

|

27 |

Internal circular grinding |

The workpiece is tapered |

The hardness of grinding wheel is too low |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

28 |

Internal circular grinding |

The workpiece shows taper and burns on the workpiece surface |

The grinding wheel is not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

29 |

Internal circular grinding |

Workpiece surface burn |

The diameter of grinding wheel is too large |

Reduce the diameter of tested wheel |

|

30 |

Internal circular grinding |

The workpiece is in the shape of a trumpet |

When there is a through-hole of countersunk grooves in the middle of grinding, the groove is in the shape of a trumpet due to the insufficient width of the grinding wheel |

Increase the width of grinding wheel |

|

31 |

Internal circular grinding |

The workpiece is in the shape of a trumpet |

When grinding the short shoulder hole, the grinding wheel comes out of the workpiece too much and causes the trumpet shape |

Choose a narrower grinding wheel or trim the diameter of the passing part of the grinding wheel a little smaller. |

|

32 |

Internal circular grinding |

The workpiece is in the shape of a trumpet |

When grinding the inner hole with keyway, the groove edge angle is caused because the grinding wheel is too wide. |

Appropriately reduce the width of the grinding wheel or embed a cushion (Bakelite or metal) in the workpiece slot |

|

33 |

Plane mill |

Ripples occur on the surface of the workpiece |

Grinding wheel is imbalance |

Correctly balance grinding wheel |

|

34 |

Plane mill |

Ripples occur on the surface of the workpiece |

The hardness of grinding wheel is too high |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

35 |

Plane mill |

Ripples occur on the surface of the workpiece |

Uneven hardness on the circumferential surface of the grinding wheel |

Select high quality grinding wheel |

|

36 |

Plane mill |

There are ripples on the workpiece surface and straight marks on the workpiece surface |

The grinding wheel has been used blunt, not sharp, and the grinding wheel has been used blunt, not sharp |

The characteristics of the workpiece and the law of precision change should be mastered, and the grinding wheel should be trimmed in time, and the characteristics of the workpiece and the law of precision change should be mastered |

|

37 |

Plane mill |

Workpiece surface burn |

The grain size is too fine or the hardness is too high |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

38 |

Plane mill |

Workpiece surface burn |

The grinding wheel is obtuse and not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

39 |

Plane mill |

Workpiece surface burn |

Grinding wheel dressing is too fine |

Choose the correct dressing method and dosage according to the grinding to be repaired |

|

40 |

Plane mill |

The workpiece squashes the horn, or the angle or side of the workpiece is in the shape of a horn, and the parallelism or flatness of the two surfaces of the workpiece is over-difference |

Improper selection of grinding wheel |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

41 |

Plane mill |

The workpiece squashes the horn, or the angle or side of the workpiece is in the shape of a horn, and the parallelism or flatness of the two surfaces of the workpiece is over-difference |

The grinding wheel is not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

42 |

Centerless mill |

Workpiece roundness error |

The grinding wheel is not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

|

43 |

Centerless mill |

Workpiece roundness error |

The surface of the guide wheel is not clean |

Clean the surface of the guide pulley in time |

|

44 |

Centerless mill |

Workpiece roundness error |

The guide pulley is not round or the working time is too long to lose the circle |

Pay attention to timely repair |

|

45 |

Centerless mill |

The workpiece is prismatic and round |

The imbalance between grinding wheel and guide wheel is too large |

Rebalance grinding wheel and guide wheel |

|

46 |

Centerless mill |

Workpiece straightness error |

The grinding wheel is too soft and poorly trimmed during cut-in grinding |

Select the harder grinding wheel, pay attention to timely dressing, reduce the feed rate, increase the number of polishing times, adjust the dresser position according to the taper direction of the workpiece, and re-trim the grinding wheel |

|

47 |

Centerless mill |

Workpiece cylindricity error |

The hardness of the grinding wheel is too low during cut-in grinding |

Choose a harder grinding wheel, pay attention to timely dressing, reduce the feed rate, and increase the number of polishing times |

|

48 |

Centerless mill |

Workpiece cylindricity error |

The grinding wheel and guide wheel have been worn out and lost their original correct shape |

Trim the grinding wheel and guide wheel in time to ensure the correct shape |

|

49 |

Centerless mill |

Workpiece cylindricity error |

Imbalance of grinding wheel or guide wheel |

Balance grinding wheel or guide wheel |

|

50 |

Centerless mill |

There are vibration marks on the surface of the workpiece |

The hardness of the grinding wheel is too high or has been used bluntly |

Correctly select the hardness of the grinding wheel according to the material characteristics of the workpiece and trim the grinding wheel in time |

|

51 |

Centerless mill |

There are vibration marks on the surface of the workpiece |

The grain size of grinding wheel is too fine |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

52 |

Centerless mill |

There are vibration marks on the surface of the workpiece |

The dressing of the grinding wheel is too rough or too smooth |

Choose the correct dressing method and dosage according to the grinding to be repaired |

|

53 |

Centerless mill |

Workpiece surface burn |

The grinding wheel is too fine or blunt |

Choose the correct dressing method and dosage according to the grinding to be repaired |

|

54 |

Centerless mill |

Workpiece surface burn |

The hardness of grinding wheel is too high |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

55 |

Centerless mill |

Numerical error of surface roughness of workpiece |

The grain size of the grinding wheel is too coarse, and the dressing of the grinding wheel is too coarse |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

56 |

Centerless mill |

Numerical error of surface roughness of workpiece |

The hardness of grinding wheel is too soft |

The grinding wheel should be correctly selected according to the characteristics of the workpiece and the grinding requirements and according to the characteristics of the grinding tool and its selection rules |

|

57 |

Centerless mill |

Workpiece size dispersion |

The grinding wheel just finished grinding is not sharp and the diamond has been worn |

Diamond should change direction or replace new one in time.

|

|

58 |

Cam mill |

The accuracy of cam lift curve is too bad |

The diameter of the grinding wheel has exceeded the allowable range of use |

Replace the grinding wheel |

|

59 |

Guide rail mill |

Workpiece deformation or fault error |

Improper selection of grinding wheel |

Select the appropriate grinding wheel according to the material and hardness of the workpiece. When the hardness of the workpiece is ≥ HRC64, the CBN grinding wheel should be selected |

|

60 |

Guide rail mill |

Workpiece deformation or fault error |

The grinding wheel is used blunt and not sharp |

The characteristics of the workpiece and the law of precision change should be mastered and the grinding wheel should be repaired in time |

Grinding is a complex system engineering, and the grinding wheel and grinding process should be correctly selected according to the material characteristics of the workpiece. When there are different grinding defects in the working conditions, the correct dressing method should be adopted, so that the workpieces with good machining quality and high dimensional accuracy can be obtained, so as to improve the production efficiency and reduce the production cost.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

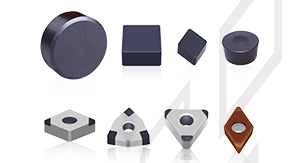

PCBN Insert

Substantially improve cutting efficiency and tool life

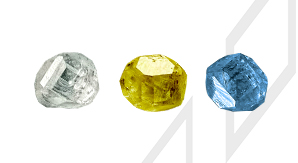

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik