The key to the effective use of PCD compact is to cut it according to the actual shape and size. During laser cutting, there is no contact between the cutting torch and the workpiece, and there is no tool wear. To process parts of different shapes, you only need to change the output parameters of the laser. Laser cutting process has the advantages of low noise, low vibration, no pollution, small machining deformation and thermal deformation, fast laser processing speed and high efficiency, so it is a more effective processing method.

In the laser cutting process of PCD, the surface diamond irradiated by laser first transforms into graphite, then the surface graphite sublimates directly or reacts with oxygen to form carbon dioxide. At the same time, under the thermal influence of laser, the deeper diamond is transformed into graphite, so the process of continuous graphitization and layer-by-layer removal is the laser removal mechanism of diamond.

The optimal laser cutting technology of PCD compact can obtain the best cutting quality and processing efficiency. It is found that the process parameters such as laser power, cutting speed, pulse frequency and defocus have a certain influence on the cutting quality. Therefore, it is necessary to analyze the influence of parameters on cutting quality from different angles to optimize the cutting process.

1.Slit width

The slit width and taper of laser cutting are quite different under different parameters, which has an important influence on the control of surface quality and dimensional accuracy of cutting tool materials. When the seam width is too large, the utilization rate of PCD material is reduced, and the tool size is not easy to be guaranteed, and the cone over-assembly produces a large grinding margin, which increases the difficulty of edge grinding.

The primary and secondary influencing factors of slit width are defocus, pulse frequency, cutting speed and laser power. Defocus has a significant effect on slit width and cutting taper. The reason is that the energy in the range of laser focal depth is high and the distribution is relatively uniform. The laser energy transmittance is low when the negative defocus is too large, and the energy diverges rapidly when the laser is in positive defocus. Laser power and cutting rate determine the amount of laser energy obtained per unit area of the material in a certain period of time. When the pulse width and frequency are constant, increasing the output power can increase the laser beam power density. Higher power density makes more vapor phase materials are produced in the machining process, and the slit width increases.

2.Processing quality

The primary and secondary factors affecting surface roughness are pulse frequency, defocus, laser power and cutting speed. When the pulse frequency increases, the laser spot overlap increases, the laser single pulse energy decreases and the peak power decreases, which can effectively reduce the slit width and improve the surface machining quality. The overlap degree of the laser spot is determined by the pulse frequency and the cutting speed. Properly increasing the laser power density or increasing the laser spot overlap degree is beneficial to improve the laser cutting quality. The higher the frequency or the smaller the pulse width is, the more serious the side burr phenomenon is. The more serious burr will have an impact on brazing at the later stage.

With the increase of laser power, the range of cutting rate is also expanded, which is beneficial to improve the stability and efficiency of cutting.

3.Micro crack

Generally speaking, the higher the laser output power, the greater the heat load in the processing process, resulting in greater temperature difference and thermal stress, resulting in larger HAZ and more microcracks. The results show that the higher the laser power is, the larger the notch width is, and the stress level decreases immediately. When the tensile stress FpullingMAX < the strength of the material, the crack will not occur. The large width of the notch dissipates heat quickly, and the heat generated in the machining process is too late to transfer to a deeper layer, so that the heat affected zone becomes smaller. High laser power is conducive to the smooth removal of materials to form a good machined surface, but it is not that the greater the laser power is the better.

Generally speaking, it is necessary to select appropriate laser cutting parameters for cutting PCD cutting tools with different brands, different material layer thickness, total thickness and even different shapes, in order to avoid appearance defects such as burr and micro-crack.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

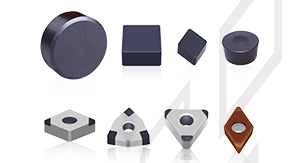

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

PCBN Insert

Substantially improve cutting efficiency and tool life

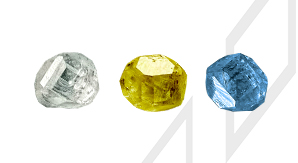

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik