Polycrystalline cubic boron nitride (PCBN) superhard material cutting tools are more and more widely used in automobile manufacturing because of their high hardness, good wear resistance and chemical stability. The research status of PCBN superhard material cutting tools for machining gray cast iron, nodular cast iron and vermicular cast iron at home and abroad is summarized and analyzed. The wear mechanism of PCBN superhard material cutting tools when machining three kinds of cast iron is analyzed mainly from the aspects of tool materials, process parameters, workpiece materials, cutting environment and machining model. Finally, the tool wear when cutting different kinds of cast iron materials is summarized.

1.Classification of common cast iron

At present, the cast iron commonly used in the field of automobile engine manufacturing mainly includes gray cast iron, nodular cast iron and vermicular cast iron. Their microstructure, properties and application characteristics are shown in Table 1. The graphite shape, matrix composition and the content of various chemical elements in all kinds of cast iron materials not only determine their different uses, but also affect the processability of the castings made of this material.

Table 1 Properties and uses of various cast iron materials

|

Cast iron type |

Graphite shape |

Performance characteristics |

Main use |

|

Gray cast iron |

Flaky |

Easy to cast, poor brazeability, good wear and shock reduction |

Gears, various boxes and bases |

|

Nodular cast iron |

Spherical |

High strength and plasticity, prone to bad spheroidization |

Automobile crankshaft, connecting rod of internal combustion engine |

|

Vermicular graphite cast iron |

Wormlike |

Good casting properties, high strength and impact toughness, wear resistance |

Automobile engine, brake disc, diesel engine cylinder head |

2.Wear of PCBN cutting tool in cutting cast Iron material

PCBN cutting tool is suitable for high-speed dry cutting gray cast iron. The main factors affecting PCBN cutting tool wear are cutting tool CBN content, type of binder, cutting tool cutting parameters and geometric parameters, workpiece materials and so on.

When machining gray cast iron and nodular cast iron, the study shows that when machining gray cast iron with the same area, the wear of PCBN cutting tools with high content (> 90%) is smaller than that of PCBN cutting tools with low content (< 75%). This is because the cutting toolswith high CBN content have higher hardness, better wear resistance and longer life. It is found that the cutting speed has a great influence on the wear mechanism of cutting tools, adhesive wear is dominant when the cutting speed is less than 150 m/min, and diffusion wear and chemical wear are dominant when the cutting speed is more than 150m/min. While vermicular graphite cast iron is difficult to machine, the main reason is that the cutting tip temperature of vermicular graphite cast iron is higher than that of gray cast iron, and the loss of sulfur is serious in the production process of vermicular graphite cast iron, so it can not form the MnS layer which can protect PCBN cutting tool when machining gray cast iron, which leads to serious chemical wear and life reduction of the cutting tool. In addition, the high content of Ti in vermicular graphite cast iron is also the cause of serious cutting tool wear. The high hardness of Ti or its compound in the workpiece will aggravate the abrasive wear of the cutting tool.

Although the cutting tool wear mechanisms are roughly the same when cutting different cast iron materials, such as adhesive wear, diffusion wear and chemical wear, the tool wear is very different. When cutting gray cast iron with high ferrite content, PCBN cutting tool is easy to form crescent depressionon the rake face, and there are many thermal stress cracks on the cutting edge. When cutting nodular cast iron, the cutting tool is easy to chip under the action of impact force, and there will also be crescent depressioncaused by adhesive wear. When cutting vermicular graphite cast iron, due to the influence of Ti element in cast iron and it is difficult to form MnS lubricating film, tool wear is more serious, mainly chemical wear such as oxidation and diffusion wear. At present, PCBN cutting vermicular graphite cast iron is not ideal, and it is necessary to study the tool material, cutting technology and wear mechanism.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

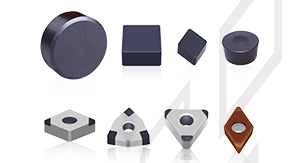

PCBN Insert

Substantially improve cutting efficiency and tool life

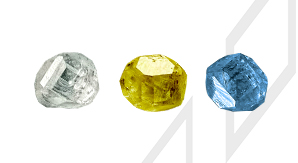

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik