The continuous improvement of modern cutting speed and the continuous development of advanced integrated manufacturing speed have put forward higher requirements for the performance of modern cutting tools, so the development of superhard cutting tools with high thermal stability and high wear resistance is the trend of today's development. Polycrystalline cubic boron nitride (PCBN) cutting tools have excellent properties such as high strength, high wear resistance, high thermal conductivity, good high temperature mechanical stability and high temperature chemical stability. PCBN cutting tools have become the research focus of industrial countries at home and abroad.

1.A brief introduction to the development of PCBN cutting tools

In 1957, GE Company of the United States first synthesized cubic boron nitride, and cubic boron nitride cutting tools were synthesized in 1973. Its materials and products have been developed for 60 years. Countries are also competing to develop superhard CBN cutting tools with excellent performance. Cubic boron nitride samples were synthesized in China in 1967, and superhard cutting tools were made in 1973 and put into production. The models and types of cutting tools in China are becoming more and more abundant, but there is still a big gap in the performance and serialization of our products compared with foreign countries. In order to shorten the gap with developed countries in the PCBN cutting tool industry, China set up a major national science and technology project of "High-end CNC Machine Tools and Basic Manufacturing Equipment" in 2010. It is clearly proposed to research and develop superhard material cutting tools and high-precision cutting tools, actively establish high-precision and high-efficiency cutting devices, and carry out a large number of experiments according to the requirements of different workpieces and machining processes to establish and improve the database of machining different workpieces with different cutting tools under different conditions and to develop a series of efficient cutting tools suitable for difficult-to-machining materials such as steel, titanium alloy, superalloy and so on.

2.Characteristics and application of PCBN cutting tool

PCBN cutting tool have high hardness and wear resistance, PCBN hardness values of different bond contents range from 40 to 60 GPa, with good heat resistance and red hardness, whose heat resistance can be up to 1400 ℃. They can effectively cut iron series materials. They have high speed cutting characteristics and high machining precision, which can continuously do dry cutting under the condition of cutting speed above 1000 r/min, achieving polished surface finish. Excellent properties such as high strength, high wear resistance, high thermal conductivity, good high temperature mechanical stability and high temperature chemical stability make PCBN cutting tools the first cutting choice to meet the current stringent cutting requirements.

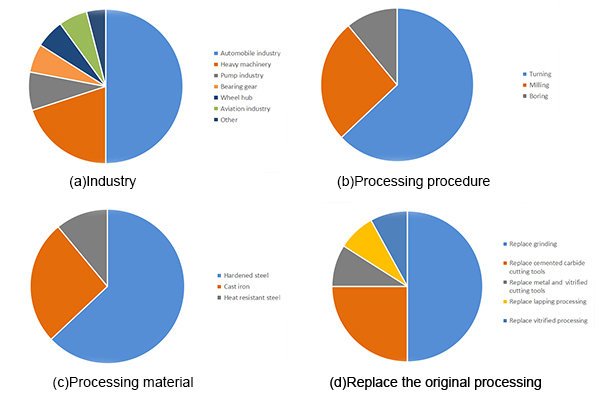

According to the manufacturing statistics, the application of PCBN in the manufacturing industry is shown in figure 1. PCBN cutting tool is mainly used on turning and machining hardened steel piecework in the fields of automobile industry, heavy machinery and others. It also reflects the good cutting performance of PCBN cutting tool. CBN is not only suitable for general cutting, but also suitable for high-speed machining. In addition, PCBN can realize hard dry cutting in the machining process. This is conducive to the realization of green cutting; at the same time, it can give full play to the cutting performance of cutting tools and metal softening effect, and can obviously improve economic benefits.

PCBN cutting tools with different CBN content are suitable for different cutting fields. HALPIN et al summarized the cutting fields of PCBN with different CBN content, as shown in Table 1.

Figure 1 Application of PCBN cutting tools at home and abroad

Table 1 Cutting field of PCBN cutting tools with different CBN content

|

CBN content |

Characteristics |

Nature |

Application field |

|

PCBN cutting tool with high CBN content |

The content of CBN is more than 80% |

High breakage toughness, high thermal conductivity |

Finishing: chilled cast iron, pearlite, gray cast iron; Roughing: hardened steel, chilled cast iron, surface hardening (cobalt-based, nickel-based, iron-based), pearlite and gray cast iron |

|

PCBN cutting tool with low CBN content |

CBN content less than 60% |

High compressive strength, low thermal conductivity |

Finishing: hardened steel and cast iron, surface hardened (cobalt-based, nickel-based, iron-based) |

3.Classification of PCBN cutting tools

According to the composition, PCBN cutting tools can be divided into two categories: PCBN cutting tools machined by CBN sintered bodies with a certain proportion of bonds and PCBN cutting tools machined directly from CBN single crystal. According to the difference of bond, it is divided into metal bond and vitrified bond. The metal softening temperature of metal bond is generally low. In the process of cutting tool cutting, local high temperature will soften and oxidize the bond, which will reduce the high temperature hardness and stability of PCBN. The vitrified bond has high hardness, good high temperature stability and good chemical stability. But its impact toughness is poor, the cutting tool is easy to chip and damage, and the service life is short. Metal vitrified type bond is mostly used in PCBN in the market. Metal vitrified type PCBN cutting tool has the advantages of both metal type and vitrified type PCBN cutting tool, which not only solves the problem that metal bond is easy to soften at high temperature, but also overcomes the disadvantage of poor impact toughness of vitrified bond.

In addition to the stoichiometric bond, the researchers explored the non-stoichiometric bond to improve the performance of PCBN; by using the vacancy effect in the non-stoichiometric ratio, activate the sintering to reduce the sintering temperature. The non-stoichiometric bond reacts with CBN to form corresponding nitrides and boride, which will greatly improve the bonding strength between the bond and CBN and improve the wear resistance of the cutting tool. The research of non-stoichiometric bonds is becoming more and more popular in PCBN.

Because the bond reduces the hardness, strength and wear resistance of PCBN, pure PCBN has developed rapidly in recent years. The hardness and thermal stability of hexagonal boron nitride directly converted to pure phase PCBN, under high temperature and high pressure with catalyst from Sumitomo is higher than that of PCBN synthesized by ordinary synthesis. High concentration PCBN is synthesized by DUB et al., by means of pyrolytic graphite BN, at 8 GPa pressure and 2200 ℃ temperature. The grain size of PCBN was 100~400 nm. For the PCBN prepared by SUMIYA et al at 7.7 GPa, and 2000~2500 ℃, CBN volume fraction is ≥ 99.9%, grain size is < 0.5 μm. The PCBN prepared has high breakage strength and hardness at any temperature.

4.Manufacture of PCBN cutting tool

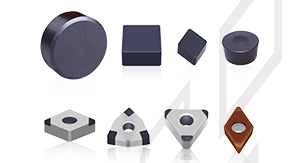

PCBN compact combines CBN material layer with cemented carbide substrate under high temperature and high pressure, and various brazed cutting tools or inserts are made by laser or WEDM, brazing and grinding process. The monolithic PCBN sintered block is directly sintered into the monolithic PCBN blank without alloy substrate, and the PCBN cutting tool is made by edge grinding.

The chip breaker which can give full play to the characteristics of the new material is designed on the PCBN cutting tool, and the shape of the chip breaker can be selected according to the different machining conditions (cutting sharpness, cutting tip strength). The chip breaker can better control the chip, because the chip breaker can: (1) control the flow direction, crimping and breaking of the chip; (2) affect the cutting force, cutting power and cutting temperature; (3) affect the durability of the tool; (4) affect the vibration of the machine tool and workpiece; (5) affect the surface quality of the machined workpiece.

The polishing edge technology on the PCBN cutting tool can improve the roughness of the machined surface, increase the feed rate, and realize high-speed cutting. Under the condition that the cutting parameters are constant, the surface quality can be greatly improved. Sandvik Coromant has introduced polishing edge technology into the field of superhard inserts, which can improve surface quality and production efficiency in finishing outer and inner circles, and has achieved great success.

The application of PCBN coating technology can improve the thermal stability and wear resistance of PCBN cutting tools. The common coatings include nitride coating of physical vapor deposition technology and oxide coating of chemical vapor deposition technology. The thickness of the coating can reach 1-20 microns; it meets the conditions of high hard turning and the requirements of rough, fine continuous to intermittent machining, and higher production efficiency can be achieved in the efficient machining of parts and components.

5.Application of simulation technology

With the development of science and technology, the finite element method and artificial intelligence algorithm simulate the field cutting tool testing with simulation technology, which will greatly reduce the frequency of previous experiments and customer testing. The simulation software can observe the data that can not be measured during cutting, such as wear form, cutting temperature, cutting stress, internal stress of machined parts, etc., and can observe the chip shape and the state of the cutting tool and workpiece at each step. With the help of software, cutting tool developers can quickly analyze the data, predict the problems in the cutting tool machining process, and adjust the material and geometry of the cutting tool timely and effectively.

In the stage of cutting tool research and development, more and more superhard material enterprises at home and abroad begin to attach importance to simulation technology, which can indeed reduce the number of experiments, reduce costs, and easily observe experimental data. However, because the ideal simulation technology limits the accuracy of the simulation, experiments need to be carried out in the later stage to verify the authenticity and accuracy of the simulation. At the same time, we need to pay attention to the establishment of a perfect cutting simulation database, the establishment of a perfect cutting tool material equation and model database, and the development of simulation software that meets the actual requirements.

6.Conclusion

Domestic PCBN cutting tool materials have made excellent achievements after decades of development, but the R&D and application of PCBN cutting tool materials and cutting tools are not as good as other manufacturing powers. We should learn from foreign R & D experience, strengthen the construction of industry foundation and application scientific research platform, innovate and develop internationally competitive PCBN cutting tool products, and realize the intelligence of design and manufacturing. Develop high-end superhard materials to support national major projects and strategic emerging industries, replace imported products, and achieve green, high-precision, high-efficiency, high-speed new superhard material tools.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

PCBN Insert

Substantially improve cutting efficiency and tool life

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik