Resin bond CBN grinding wheel is a kind of grinding tool with certain rigidity (strength and hardness) by using organic polymer compounds as bond to consolidate CBN abrasive together. Resin bond CBN grinding wheel can process all kinds of metal and non-metal materials, especially in the field of fine grinding and polishing. It is suitable for grinding workpieces such as high speed steel, cast iron, stainless steel and nitride stainless steel. It is more and more used to replace common grinding tools on low speed grinding machines. It is widely used in precision grinding of iron-containing workpieces in automobile, bearing, compressor, precision mold and other industries or fields, and it is an irreplaceable tool in grinding.

Resin bond CBN grinding wheel is widely used in rough, fine, polishing and other grinding processes. Its resin bond CBN grinding wheel has the following characteristics:

(1)High bonding strength. Compared with vitrified bond, the bonding strength of resin bond CBN grinding wheel is higher, the grinding and cutting speed of resin bonded grinding wheel is up to 80~120m/s, and it can bear higher grinding pressure.

(2)It has a certain degree of flexibility. Compared with vitrified bond CBN grinding wheel, resin bond grinding wheel has good toughness, plasticity and ductility, so it is suitable for preparing various specifications of sheet grinding wheel and high-speed cutting grinding wheel. Because of the certain elastic deformation, it can buffer the grinding force, so the grinding effect is good, the polishing effect is good, and the roughness of the machined surface can be improved.

(3)Can be made into a variety of complex shapes and special requirements of grinding tools. Due to the low hardening temperature of resin bond CBN grinding wheel, it can be hardened at room temperature and the shrinkage is small, so it can be made into grinding wheels of various complex shapes and special requirements.

(4)It is helpful to prevent burns of the ground workpiece. The heat resistance of the resin bond is low, and the heat generated by the workpiece in the grinding process carbonizes the resin, promotes the honed abrasive to fall off automatically, reveals new sharp abrasives, reduces the heat in the grinding area, and avoids workpiece burns.

(5)The hardening temperature is low. Resin CBN grinding wheel has the advantages of low hardening temperature, short production cycle and simple equipment, which is beneficial to specialized production.

However, compared with other bond grinding wheels, the shortcomings of resin bond CBN grinding wheels are: poor alkali resistance and water resistance, easy aging; low heat resistance, large wear during grinding, which is not suitable for shaping grinding; low porosity, odor in processing, which is easy to cause environmental pollution.

CBN abrasive is the dominant factor in grinding. The CBN abrasive used in resin bond CBN grinding wheel often has the following common characteristics:

(1)The crystal shape is irregular and most of the grains are non-equal area shape.

(2)The grain surface is rough and not smooth.

(3)Low strength and high brittleness.

(4)The thermal stability is poor. CBN abrasives with these characteristics are suitable for manufacturing resin bond grinding wheels for the following reasons: First, the holding force of resin on abrasives is weak, the surface of abrasives is rough and irregular, which is favorable for mechanical occlusion with resin; Second, the resin bond itself has low strength, low manufacturing and use temperature, and does not require high strength and heat resistance of abrasives. Brittle grains only need low working pressure (normal grinding force) in grinding to show micro-edge fracture and show good self-sharpening, which is the root cause of low grinding force and low grinding temperature of resin grinding wheel.

CBN/DIA Superabrasive

Improve grinding efficiency to a new level

PCD Blank

Improve the comprehensive competition advantages of cutting tool manufacturer

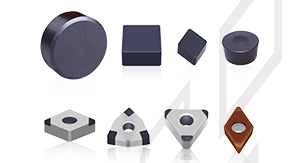

PCBN Insert

Substantially improve cutting efficiency and tool life

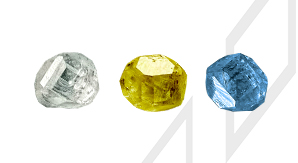

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of Funik